Over the past five years dramatic changes have occurred; changing the way weighbridge systems are required to operate and how they integrate with peripheral vehicle control equipment and established management software systems. However, there is evidence that performance, reliability and functionality are being compromised through the emergence of lower priced weighbridge systems with questionable long term credentials. Although these may seem initially attractive, the consequences of buying on price alone can be very problematic and expensive.

So what are the critical design and operational issues which potential purchasers of weighbridge systems should consider from the outset? As Weightron Bilanciai’s Sales Director Emlyn Roberts explains, three distinct areas need to be considered:

- The design and build of the weighbridge itself;

- The pedigree of key measurement chain components (load cells and instrumentation);

- Software functionality and software integration.

Weighbridges:

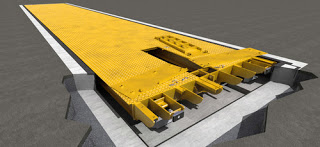

Weighbridges may seem to be merely pieces of metal or concrete, but sound mechanical design and build procedures are essential both for performance and longevity. In parallel, well designed foundations and vehicle approach areas play a vital role. Cutting corners with factors such as steel quality, weld integrity or surface finish may reduce prices, but this can have a detrimental effect on overall reliability and longevity.

Load Cells:

The load cells and their associated mounting hardware are considered to be the most crucial part of the weighbridge and are required to work under a range of harsh and challenging environments. Therefore design and application optimisation for these essential components is crucial; not only for performance, but also for long term reliability.

Of all the designs, clear evidence from the field shows that compact stainless steel canister load cells, together with well-designed rocker mounting assemblies provide the optimum solution for weighbridges. More cumbersome single ended bending beam load cells or vulnerable double ended shear beams with ball bearing mountings are more likely to fail and generally require more ongoing maintenance. It should be remembered that weighbridge decks can be subject to relatively large expansion-contractions, which affect the load introduction angles and this places further importance on the requirement for well designed load cells and mounting assemblies.

Instrumentation:

Traditional weighbridge instrumentation has developed significantly over the past two to three years. Intuitive touch screen terminals have replaced standard weight indicators and provide a wealth of operational and management features. End users should explore the future proof capabilities of instrumentation and investigate how easy it is to set up fundamental features such as databases and libraries. Driver terminals must be capable of operating with the wide array of recognition technologies such as RFID, magnetic and voice activation.

Software:

Today’s weighbridge systems are expected to seamlessly integrate with an array of management software systems including SAP, Sage, Microsoft Dynamics and J D Edwards. However, although system functionality for a specific project may appear to be well defined at the outset, functional design specifications invariably change throughout a project. As a result it is therefore beneficial for the weighbridge supplier to take responsibility not just for the weighbridge software, but also for the all-important interface between the weighbridge system and the overall plant management system. The use of third party software suppliers, who have little or no knowledge of weighing, can turn out to be more complicated and expensive in the long run. In parallel the weighbridge software must be fully compatible with the growing range of peripheral equipment including automatic number plate cameras, control barriers, traffic lights and card readers.

Service and Support:

Effective rapid response support is essential for weighbridges to minimise downtime. This is far easier if the original supplier has supplied and installed the complete system and also has readily available trained engineers.

Conclusion:

As weighbridge systems become demanding and operationally complex, the pitfalls of buying on price increase. It is recognised that cost is an important factor, but the apparent advantages of initial low prices can soon be lost through unreliability and operational limitations.

Source Link

Other Articles from Weightron Bilanciai Ltd (UK)

© Weightron Bilanciai Ltd (UK) / International Weighing Review

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.