Are you looking for High Quality websites where you can publish your Articles?

- April 27, 2024

Are you in search of reputable platforms for publishing high-quality articles? If your vocabulary often includes terms like SEO, link building, guest...

Read MoreHBK Webinar: Why digital sensors are the future - force, torque and load with IO-Link

- April 26, 2024

HBK - Hottinger Brüel & Kjaer (Germany) - Webinar: Why digital sensors are the future - force, torque and load with IO-Link. The digitalisatio...

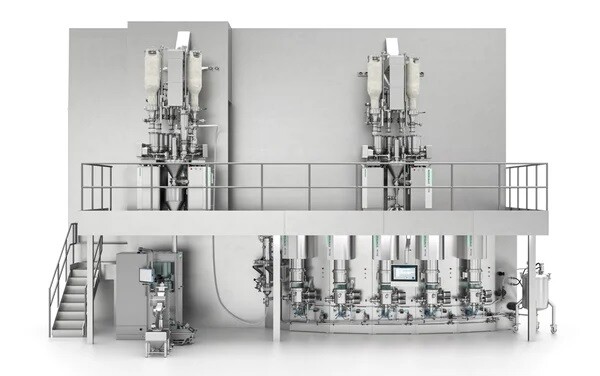

Read MoreSyntegon at Achema: the highest flexibility for oral solid dosage processing

- April 26, 2024

Syntegon Technology GmbH (Germany) - Press Release: Syntegon at Achema: the highest flexibility for oral solid dosage processing. Exemplary OSD...

Read MoreIntroducing Paxiom’s Turn-Key Bulk Nut Vacuum Packaging System

- April 26, 2024

Paxiom Group (United States) - Introducing Paxiom’s Turn-Key Bulk Nut Vacuum Packaging System We are excited to announce the installation of...

Read MoreNew Approvals for Group Four Sucker Rod Load Cell

- April 25, 2024

Group Four Transducers Inc. (United States) - Press Release: Group Four has achieved EN IEC 60079-0:2018 and EN 60079-7:2015 approval of their sucker...

Read MoreJob Offer by HBK - Hottinger Brüel & Kjaer: VP - Services and Solutions

- April 25, 2024

HBK - Hottinger Brüel & Kjaer (Germany) - We are currently looking for a Vice President Services and Solutions for our Physical Test Business Uni...

Read MoreOutsourcing: A Game-Changer for Customer Support

- April 25, 2024

[Article]: Outsourcing: A Game-Changer for Customer Support Recently, outsourcing has become increasingly popular. Companies outsource their busine...

Read MoreJob Offer by Micro Weighing Solutions - MWS Ltd: Field Service Engineer – Midlands

- April 24, 2024

Micro Weighing Solutions - MWS Ltd (United Kingdom) - Field Service Engineer – Midlands. Department: Service Type: Full Time Location:...

Read MoreArticle By SCAIME: Weighing solutions for intralogistics

- April 24, 2024

SCAIME S.A.S. (France) - Weighing in intralogistics: flow optimization and intelligent inventory management... Intralogistics, which refers to the...

Read MoreNew Ishida Europe Checkweigher Range Meets European Market Needs

- April 24, 2024

Ishida Europe Ltd. (United Kingdom) - Press Release: Ishida Europe is launching an enhanced range of checkweighers designed to meet latest European ma...

Read MoreGeneral Measure Checkweigher CW-15K in Food Industry for Box Weight Checking

- April 19, 2024

General Measure Technology Co. Ltd. (China) - The CW-15K online check weigher has a wide weight range and high accuracy, And it can run with...

Read MoreThe Origin of the New Brand Dynascales

- April 18, 2024

Weighing & Inspection (Belgium) - Press Release: About the origin of our new brand Dynascales. Being a productline of Weighing & Inspection...

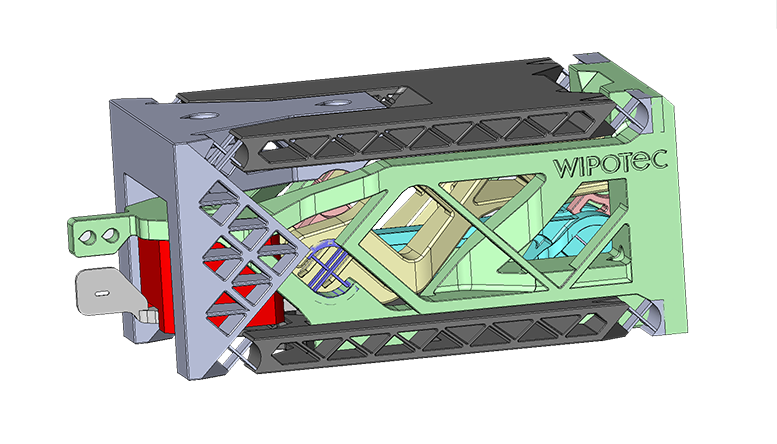

Read MoreArticle by Wipotec: Weigh Cells: Monoblocks from 3D printers

- April 18, 2024

WIPOTEC GmbH (Germany) - Weigh Cells: Monoblocks from 3D printers. The central element of scales is a Weigh Cell with its monolithic controller and...

Read More30 years of SysTec: company anniversary

- April 17, 2024

SysTec Systemtechnik und Industrieautomation GmbH (Germany) - Press Release: 30 years of SysTec: company anniversary. Weighing technology combines...

Read MoreThayer Scale introduces new WeighPoint integrator

- April 17, 2024

Thayer Scale-Hyer Industries, Inc. (United States) - Press Release: Thayer Scale, a leading global manufacturer of equipment for the continuous weighi...

Read MoreHow to Start a Delivery Service Business

- April 16, 2024

[Article]: How to Start a Delivery Service Business. The delivery service market is booming, with more and more consumers demanding instant doorste...

Read More