The almost universal task in business today is to increase quality while decreasing lead time. The field of weight calibration is no exception, as it becomes more and more difficult for customers in highly regulated industries to wait for calibrated weights.

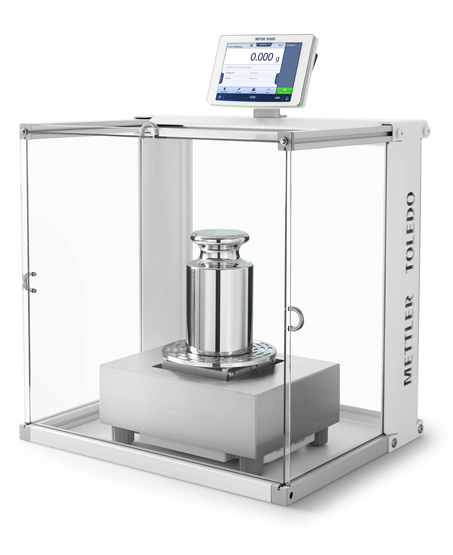

XPR mass comparators are helping labs and industrial clients provide intuitive, efficient and secure weight calibration processes at higher throughput. The comparators’ high repeatability and ability to support low minimum weight values make them the preferred choice for not only weight calibration but also accurate measurement of extremely small goods at high tare loads.

XPR’s sensitive, worry-free mass determination is assured by a range of METTLER TOLEDO features that enhance both accuracy and processing speed:

- LevelMatic delivers the utmost in reliability by reducing corner-load effects to an absolute minimum.

- MC Link calibration software offers flexible calibration process configuration, on-screen user guidance, automatic calculations and comprehensive data handling for easier, faster processes. MC Link also manages measurement uncertainty. All process information and calibration data are stored securely in a central database to fulfill your highest process-security requirements. Calibration certificates are printed with just one click.

- The addition of StatusLightTM means operators never weigh when the comparator is out-of-calibration or off-level. A built-in indicator registers green when it is safe to calibrate, yellow when an issue needs attention, and red when a particular test is outdated. The user has the security of knowing that all results acquired meet predefined process requirements and relevant regulations.

Overall, these features help to streamline your daily task list and ensure the kind of accuracy demanded by your industry and clients. This helps you improve measurement quality while also enhancing throughput.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.