METTLER TOLEDO (Switzerland) - METTLER TOLEDO has released an update for the MS-TS analytical and precision balance lines which offers advanced connectivity, publishing and reporting features for improved data management and process control. With Ethernet and Wi-Fi options, connection to peripheral devices or LAN/WLAN networks is easier and more flexible. Data transfer from the balance to other devices is faster and easier. Save, print or export weighing results in a variety of formats, to different places simultaneously. Web browser access to the balance terminal offers convenient viewing of results remotely.

METTLER TOLEDO is pleased to announce an upgrade to their MS-TS advanced level analytical and precision balances, which provides advanced connectivity and reporting capabilities for easier data management. The new hardware, with integrated Ethernet interface, and updated software are designed with connectivity in mind. They offer greater flexibility in connectivity and reporting options, to make transfer of weighing results as easy and convenient as possible, whether for archiving or for further processing. In addition, launch of the new wireless dongle, offering Wi-Fi and Bluetooth capabilities, which allows easy connection to any WLAN, wireless hotspot or to a P-50 laboratory printer.

Advanced Connectivity Options to Optimize Process Control:

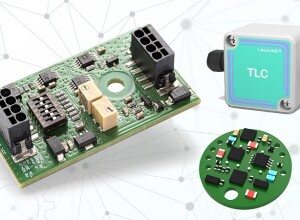

MS-TS advanced level balances are equipped with four interfaces and various services for easy connectivity. With the choice of built-in Ethernet, USB Host, USB Device and RS232 interfaces, it is quick and easy to connect MS-TS Advanced Level balances to peripheral devices and company networks (such as LAN, PC, USB memory stick, printer, barcode reader, keyboard or auxiliary display). New functionality allows data transfer directly to an FTP server. With the additional options of WLAN and Bluetooth, via the new wireless dongle, transfer of weighing data is simple and convenient. Features such as Balance Web Access enable remote viewing of weighing results, by accessing the MS-TS balance from a web browser on any tablet or PC. This makes it possible to view weighing results from anywhere within your company network, as well as perform basic balance operations such as tare or print, from a second screen.

Advanced Reporting and Publishing for Easier Data Management:

Advanced reporting and publishing options for MS-TS advanced level balances offer flexibility on how to save, print and export weighing results and associated metadata. Reports can be tailored to the user or process to further improve productivity whilst controlling product quality. Operators can customize the inclusion of weighing metadata to results reports according to their requirements. For example, information about balance setup, including the leveling status and the last adjustment, can be appended to support the accuracy of results. A variety of formats are available with the latest software version: PDF, TXT, XML, and CSV. This allows weighing data to be transferred to a file server as a PDF report, which is ideally suited to on-screen viewing or electronic archiving. Alternatively, for further processing and analysis, data can be conveniently saved in standard CSV or XML file formats, either on to a USB memory stick or directly exported to an FTP server. Simultaneous publishing of different formats over different interfaces is also possible. For example, the balance can simultaneously send measurement reports to a strip printer via USB, for archiving in a lab journal, and send more comprehensive data files directly to a networked printer or FTP server via Ethernet.

Effortless Management of Weighing Results:

Whether used in a laboratory or on the production line, MS-TS balances deliver highly reproducible results, with maximum connectivity to guarantee convenient, simplified and secure reporting. Ensuring your laboratory balance can effortlessly print, store and transfer weighing results supports downstream data accuracy and the quality of the final products. Efficient data handling with access to a range of connectivity and flexible publishing options enables better process control, ensures that relevant data is easily accessible, and supports the audit-trail.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.