Interface, Inc. (United States) - Industries: Industrial Automation.

Summary:

Customer Need / Challenge:

To meet safety protocols in relation to the manufacturing of various furniture products, fatigue testing, shock testing, and proof testing must be rigorously performed before diffusion into the marketplace. Force testing simulations on furniture products are critical in determining the posted max loads in order to protect manufacturers from liability due to damages that might result from the misuse of those products and overloading.

Interface Solution:

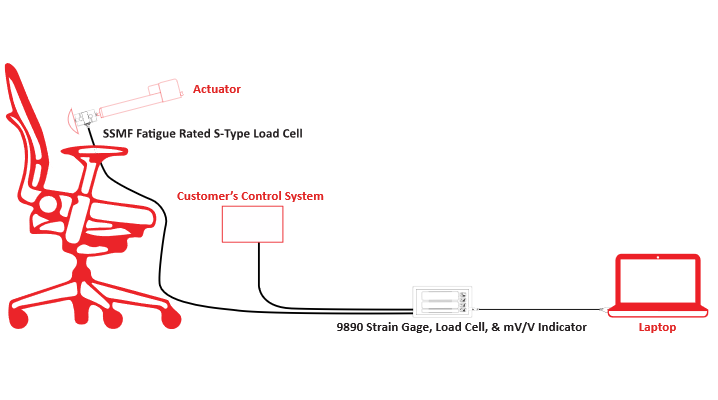

Using an Interface Model SSMF Fatigue Rated S-Type Load Cell along with Interface Model 9890 Strain Gage, Load Cell, & mV/V Indicator provides a solution that measures the force being applied in fatigue cycle testing of a furniture product, in this case testing the rocking mechanism in an office chair. Unlike other similar load cells, the Model SSMF is fatigue rated making it highly suitable for fatigue testing. No fatigue failure of any fatigue-rated Interface load cell, used within it’s ratings, has ever been reported.

Results:

The furniture manufacturer was able to obtain accurate data about the rocking mechanism the office chair as it was fatigue cycled into failure. Adjustments were made to the design to improve the safety and life of the furniture, ensuring product quality and protecting the manufacturer from future liability.

Materials:

- Model SSMF Fatigue Rated S-Type Load Cell.

- 9890 Strain Gage, Load Cell, & mV/V Indicator, which comes standard with logging and configuration software.

How it works:

- Determine the feature on the product to be tested, and build an apparatus that will focus loads into that area.

- Once the load applicators or cylinders are in place, install the Model SSMF Fatigue Rated S-Type Load cell somewhere along the direct line of force between the cylinder and the load affected area.

- To read the load forces, connect the 9890 to your load cell and to your computer before testing. It is important that any wires or cords be free of any possible snag points, crush points, or other clearance issues for the entire cycle of movement.

- Once the testing apparatus is setup and data is ready to be recorded, the test may begin. Observe all safety rules and keep a safe distance from the test during load cycling to prevent injury in the event of failure.

Related Products:

- SSMF Fatigue Rated S-Type Load Cell (25 lbf to 2.5K lbf, 100 N to 10 kN) (Image 2).

- 9890 Strain Gage, Load Cell, & mV/V Indicator (mV/V Input Indicator) (Image 3).

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.