Hardy Process Solutions (USA) - Unique new design significantly reduces installation, calibration and maintenance costs.

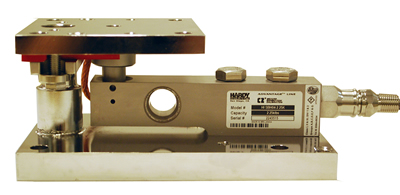

Hardy Process Solutions has introduced OneMountTM Advantage® shear beams. Hardy’s new design allows a vessel or hopper to be installed, bolted and welded using the mount itself – without installation accessories that can increase a customer’s capital investment by thousands of dollars, as well as labor costs associated with removing components after installation. OneMount Advantage’s integral spacers carry the full-rated capacity without the load cells installed, eliminating the need for the expensive dummy load cells or weighting fixtures typically used to avoid damaging the load sale during the welding process. The 360° checking mechanism allows load points to be installed in any direction and Hardy’s proprietary C2® electronic calibration and matched load cells further speed up the installation process. Maintenance is fast and easy also. Load cells can be replaced with minimal tank jacking (1/8”), and matched mV/V/ohm load cells can be replaced without recalibration.

Hardy OneMount Advantage shear beams are highly accurate and consistent due to a self-centering rocker design maintains alignment under considerable shear forces. Hardy’s innovative precision sensor (combined error 0.02% rated output) has capacity of 1,125 lbs. to 22,500 lbs.; optional dynamic stabilization rods are available to reduce vibration noise on the sensor for better resolution.

Hardy has also made safety testing and documentation a priority. Third party destructive testing of OneMount Advantage confirms liftoff and side force ratings, making it easier for systems integrators and engineers to evaluate the structural integrity and safety of their designs. True glass-to-metal hermetically sealed sensors provide IP68/IP69K-rated washdown protection. (Potted sensors offer economical options for IP67 ingress production.) Hardy’s C2® cloud-based calibration reduces risk of accidents and contamination from test weights.

This website uses cookies. By browsing our website you accept the use of cookies. For more information read our Terms of Use.

Hardy Launches OneMount Advantage® Shear Beams

- By Hardy Process Solutions

- Posted on Sep 22, 2016

For more information about this article from Hardy Process Solutions click here.

Other articles from Hardy Process Solutions.

Interesting Links:

List all your Scales and other Weighing Products (new and used) on our Marketplace !

Visit AutomationInside.com for Automation and Technology Related News!

Are you interested to include your Link here, visible on all WeighingReview.com articles and marketplace product pages? Contact us

List all your Scales and other Weighing Products (new and used) on our Marketplace !

Visit AutomationInside.com for Automation and Technology Related News!

Are you interested to include your Link here, visible on all WeighingReview.com articles and marketplace product pages? Contact us

© Hardy Process Solutions / International Weighing Review

Previous article

Fairbanks Scales announces latest generation FB6000 Weighing Instrument with intuitive Web Interface

Next article

EXCELL Introduces the New BLE Large LED Remote Display for Scales

Popular News

Weighing Review Newsletter

Popular Tags

Login

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.