Precisa (Switzerland) - High-resolution force restoration weighing cells are usually based on two different concepts. Each of them has specific advantages and disadvantages which will be discussed in detail below.

- Conventional weighing cells consist of a number of individual components. They are very flexible regarding to the choice of material, but require a high degree of assembly effort and assembly skills. They can be repaired if necessary.

- Monolithic weighing cells, which are usually made of one aluminium block, have a well-defined temperature behaviour and require only a small assembly effort. Advantageous is their relatively high degree of automation during production process. Disadvantageous is that they can’t be repaired by concept.

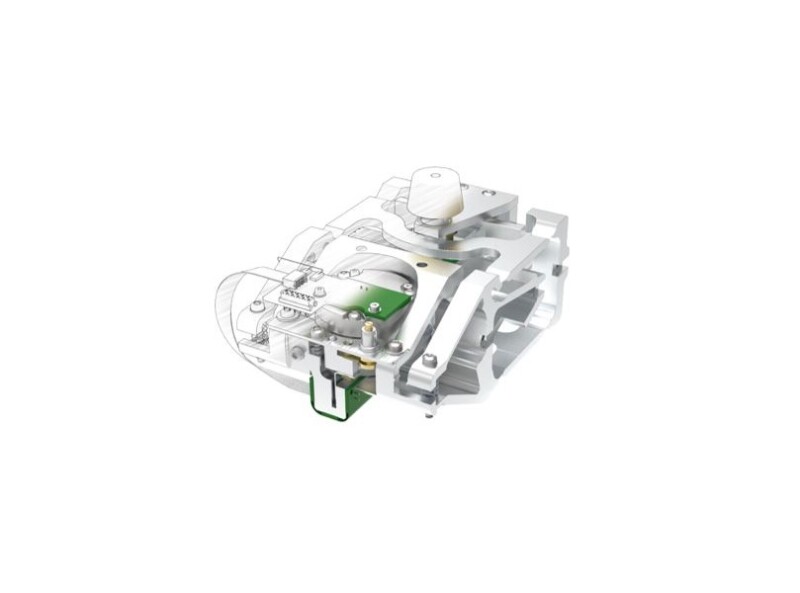

Precisa Hybrid Concept:

Precisa has set itself the task of developing a precision weighing cell which combines the advantages of both designs and is thus a very flexible and cost-effective alternative to the known designs.

The Precisa Hybrid concept follows a fundamentally different technical approach. Hybrid load cells are not manufactured from a single block, but consist of 3 monolithic functional units based on individually matched aluminium alloys. This has the following decisive technical advantages:

Advantage 1:

By dividing the system into functional units an individual adjustment with regard to the optimal production process and choice of aluminium alloy can be achieved. This is a significant advantage over monolithic cells as these are manufactured from a single block and therefore always represent a compromise between cost and material properties.

Advantage 2:

Precisa Hybrid load cells can be repaired. When a repair is carried out, only the affected functional units (layer A and layer B) need to be replaced. Therefore costs and resources can be saved.

Monolithic systems cannot be repaired by concept and must be disposed of in case of a mechanical defect. This makes no sense from an ecological and economic point of view.

Advantage 3:

Depending on the manufacturing process monolithic cells tend to have a poor material utilisation grade. During production, a large amount of high-quality and expensive aluminium alloy is milled away. This is neither ecological nor economical.

Precisa hybrid cells are based on a combination of processes (casting, milling, extrusion). This eliminates many machining operations, as the blank part already contains the essential structures without losing the thermal advantages of the monolithic concept.

Advantage 4:

Only Precisa hybrid cells allow a targeted optimisation of individual functional units, as they are manufactured separately and are therefore physically accessible.

For example, the most stressed component (layer A & B) which introduces the weight force into the sensor are subjected to an optimisation process (thermal & mechanical), which further improves the mechanical properties.

Advantage 5:

The Precisa hybrid cells can be easily scaled. For larger loads or platforms, the width of the cell can be varied by simply cutting it to the right length.

Monolithic manufacturing processes (especially EDM) are limited in terms of maximum width. The manufacturing tolerances increase with cell width.

Advantage 6:

Since the hybrid cell is based on only 3 functional units, the assembly effort is comparable to that of monolithic cells and does not require any special assembly skills.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.