Kistler Group (Switzerland): In recent years, weigh-in-motion (WIM) technology has proven to be an ideal solution for direct enforcement in road traffic control. Where high speed WIM systems previously simply helped identify vehicles that violated weight limits, they are more and more used to directly penalize overloaded vehicles.

Overloading – be it accidentally due to negligent vehicle loading or intentional as a cost-saving measure – affects road traffic in a number of ways. In the first instance, it damages infrastructure, reduces road safety, and increases unfair competition between transport modes and operators. Overloading also violates taxation rules, such as vehicle registration fees, axle taxes, and toll infrastructure fees. As a result, addressing the issue of overloaded trucks by enforcing vehicle weight and dimension regulations is essential.

The integration of advanced truck load monitoring systems into Intelligent Transport Systems (ITS) marks a significant step forward compared to compliance officers’ long-established roadside enforcement methods. Traditional enforcement is complex and time consuming, with only five to six large vehicles being handled per day on average.

WIM systems can measure vehicle loads at high speeds. They collect traffic data continuously, producing data sets that can help identify operators who are transporting goods without the correct permit. While the results vary from country to country, up to 100 violations can be identified per day. The procedure is similar to automatic speed enforcement: WIM systems can be operated 24/7, do not require enforcement personnel and are suitable for motorways with a high volume of vehicles. The most important benefit of WIM systems is automatic direct enforcement, which means that traffic is measured constantly and consistently.

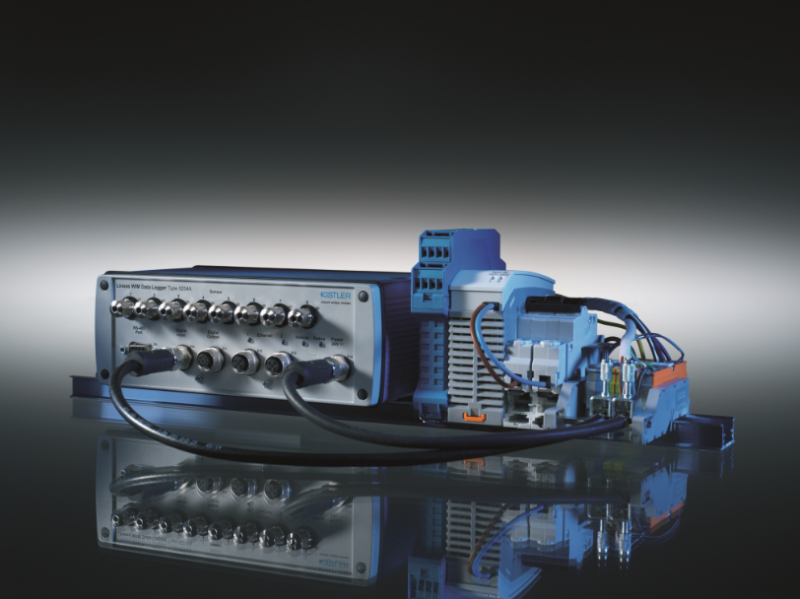

In 2015, Kistler was the first WIM manufacturer to receive the OIML (Organisation Internationale de Métrologie Légale) R-134 certificate for vehicle weighing using strip sensors at 3 to 65 km/h. This certificate recognizes that Kistler’s WIM systems, comprising the maintenance-free Lineas® quartz WIM sensors and the Kistler WIM data logger, can be used for legal weighing applications. The systems provide reliable data on traffic volume, axle loads and gross vehicle weight.

Legislation in Eastern European Countries paves the way for direct enforcement:

A number of Eastern European Countries have put legislation in place that permits the application of WIM technology in traffic enforcement. Most of these systems – provided by different system integrators – use Kistler quartz sensors for data acquisition. The Lineas Quartz WIM sensor measures wheel and axle loads extremely accurately in order to determine gross vehicle weight under rolling traffic conditions. Kistler’s WIM equipment offers a number of flexible and maintenance-free traffic monitoring options.

“In Eastern Europe we are witnessing a rapidly rising demand for WIM technology for direct enforcement applications from all sectors - federal, regional and private,” says Tomas Pospisek, EMEA Sales Manager for Road & Traffic at Kistler. “In Russia, we have observed a trend towards direct enforcement. In 2017, we gained market shares in the highly competitive market by installing WIM technology in various direct enforcement projects. Customers especially value our numerous regional sales and support centers”, adds Pospisek.

New WIM projects with Kistler equipment are also being implemented in Hungary. One of the largest WIM projects in Europe – with 89 sites nationwide – includes the installation of a large quantity of WIM sensors on a weekly basis. Each site has two to four lanes and is equipped with a tolling system. “Since 2016, we have experienced an increased demand for extended warranty. Our customers see their WIM system installations as valuable investments that need regular care. We therefore offer the typical one year warranty plus an additional 24 months,” explains Pospisek. The longevity of Kistler sensors allows for a trouble-free lifecycle.

Industrial truck weighing also has a huge potential for highly accurate, certified WIM systems. When weighing vehicles leaving or entering industrial plants, mining facilities or ports and terminals, measurement speed and overall efficiency play an important role. This is particularly true for sites with a high density of traffic, where weighing is time-consuming and expensive.

The Future of WIM Applications:

Significant progress has been made in recent years to improve and implement WIM systems, which contributes to safer and more efficient vehicle operations. Manufacturers are continuously developing new WIM features in order to keep up with the wide range of applications that go beyond enforcement. For example, WIM-systems are also being used for toll collection based on actual vehicle weight in China and South-East Asia. The technology facilitates tolling and weighing vehicles at the same time without interrupting traffic flow. “We see a similar trend in Europe. Kistler plans to expand its sensor and system portfolio to cover even more WIM applications. From this year onwards we also want to provide more services in order to meet the needs of WIM users,” says Pospisek. “Our weather-proof technology provides reliable and accurate data, which is backed up by a proven track record of successful projects”, Pospisek concludes.

About the Kistler Group

Kistler is the market leader in dynamic pressure, force, torque, and acceleration measurement. Cutting-edge technologies provide the basis for Kistler's modular systems and services.

Customers in industry, research, and development benefit from Kistler's experience as a partner, enabling them to optimize their products and processes so as to secure sustainable competitive edge. Kistler plays a key role in the evolution of automobile production and industrial automation. Drawing on its vast application expertise − and always with an absolute commitment to quality − Kistler drives innovations ahead in areas such as lightweight construction, vehicle safety, reduction of gas emission, and Industry 4.0.

The Kistler Group is an independent, owner-managed Swiss corporation. More than 1 600 employees at 58 facilities worldwide are dedicated to the development of new measurement solutions, backed by individual application-specific support at the local level. Ever since Kistler was founded in 1959, the company has grown hand-in-hand with its customers. In 2016, it posted revenue of USD 364 million, about 10% of which is reinvested in innovation and research – with the aim of delivering better results for every customer.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.