Zemic Europe B.V. (Netherlands) - Why Pack Tools integrates Zemic load cells in their XTE-motion®.

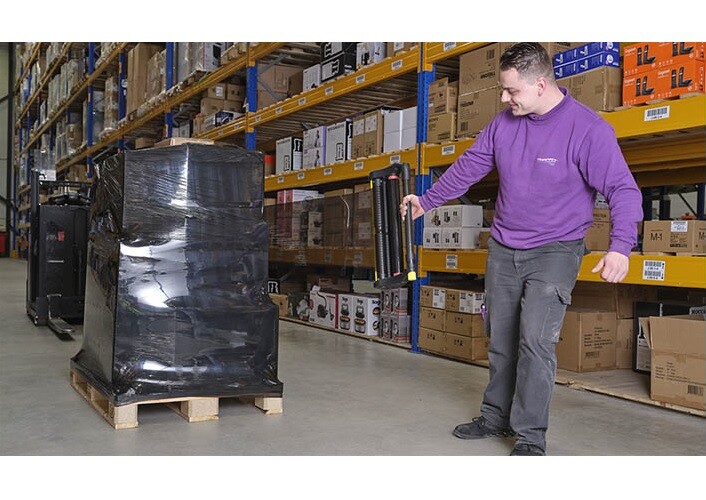

Hand pallet wrapping to pack pallets is a time-consuming activity for many companies. Pack Tools 2.0 BV is a company that develops smart tools for packaging. They took up the challenge to bring hand pallet wrap to a professional level.

Recently they have developed a solution for the optimisation of hand pallet wrapping. It is called XTE-motion®.

The XTE-motion® is an electronic hand wrap dispenser. It offers load stability and many other advantages. It makes the work more easy, efficient, safe and comfortable. In addition it makes the process more sustainable because much less plastic is used.

In order for this system to work properly, it is necessary to measure force. That is why Pack Tools contacted Zemic Europe.

We are pleased that Pack Tools approached us to help with this development. As a leading manufacturer and designer of load cells we like to think along with our customers. We always want to find the best solution for any question concerning force measurement. It is a great challenge to participate in an innovation that offers so many benefits to users and which also contributes to greater sustainability.

Zemic Europe & Pack Tools:

- Partner for smart packaging solutions

- Most efficient hand pallet wrapping system

- Custom-made load cells to exactly fit to this innovation

- High quality load cells, essential for the functioning of the XTE-motion®

- An innovation that promotes sustainability

How Zemic Europe advised Pack Tools:

When wrapping a pallet, it is important that the film is wrapped with a constant force on the pallet. The XTE-motion® gives this force and needs a force sensor to measure the force given by an operator. The system adjusts the force to be applied accordingly.

It regulates the speed and force with which the film is wound. This ensures that it is wrapped firmly enough and that not too much film is used. In this way operators don’t have to pull hard anymore and their wraps are even tighter and stronger.

During the development process, Pack tools has used some load cells for the concept versions. They found that these ‘standard’ load cells were not adequate for proper functioning of their system. So they needed advice and searched for a professional partner. From their network they got the tip to contact Zemic, because of good experiences.

For us it was a great project. Nice to work with such driven and enthusiastic developers. We could give the needed advice and developed a custom-made sensor, that fits exactly the needs. The sensor has the right format to fit in the XTE-motion®. It has the right connector, custom cable length and the desired capacity. We also made sure that the bearing fits into the load cell directly. The XTE motion® system is patented and the Zemic sensor is essential in it for its proper functioning.

Which Zemic product is used for the XTE-motion®?

For this project we developed a custom-made sensor. This sensor meets the required specifications concerning:

- Dimensions

- Cable length

- Capacity

- Connector

- Accuracy

Zemic is specialist in custom made sensors

Zemic has a specially equipped sensor department, for the design, sampling and production of your custom made force sensors. Daily 225 engineers are working on special custom made force sensor solutions. We like to think along with you for the best solution. We have the production facility to accommodate small batches of sample pieces or to mass produce millions of sensors. Read more about our custom made products.

More about the XTE-motion® and the Smart App

As described the XTE-motion® is an electronically driven dispenser to pack pallets and to optimise the hand wrapping process. It uses a high-tech Striqta® stretch film. The dispenser stretches this film to its optimal point of elasticity and rigidity without tearing or breaking. The motor driven system in the XTE-motion® takes the load of your hands.

The XTE-motion® dispenser has many advantages:

- By using the system wraps are tighter and stronger and the load is much more stable.

- Pallet loads are 100% safely secured

- Pallet loads are 100% according to international transport recommendations, so fines for unsafe loads will be avoided.

- The system improves ergonomics; operators do not have to pull hard, they do not have to kneel or bend anymore and their work is easier and more comfortably.

- The work is more efficient, so less time is needed for packing.

- The system improves internal safety in distribution centres

- Save on purchasing: the system works with sturdy plastic that is stretched so that it sits very firmly and uses less plastic.

- Reduce companies CO2-footprint

- Considerably lower tax amounts for single-use plastics.

Smart App to adjust personal settings:

To make the use even more easy there is a smart app available with the dispenser.

Operators can adjust personal settings via the app. In this way the app helps to wrap the pallet correctly for safe transport, based on the weight and load configuration of your pallets.

The app also provides management insights like the number of wrapped pallets and the operating time and film usage.

Woud you like to know more about the XTE-motion®?

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.