Weighing Review Awards 2019

Nominated for Best Load Cells

Straightpoint Bluelink Dynamometer

Designed to replace outdated mechanical products still in the field this 14,300lb (6500kg) Dynamometer, the “BlueLink” is the latest SP product to feature our proprietary Bluetooth wireless technology.

The Bluetooth signal effortlessly connects to any iOS or Android smartphone that has our free HHP app installed and provides the operator a wireless range of up to 328ft or 100m – allowing them to stand themselves in a safe position from the load with no requirement to read a load on the loadcell itself. The app will also allow the operator to log data versus time or on events such as over or underload and the adjustable alarm will alert the operator on their smartphone if any overload is occurring.

Rigged using industry standard shackles such as Crosby G2130 the Bluelink has been designed to minimise headroom (just 6” or 156mm from eye to eye) and its compact lightweight design does not sacrifice on strength with a safety factor of over 500%.

Constructed from high quality aerospace grade aluminium and hard anodized it features an advanced internal design structure. This design not only provides the product with an unrivalled strength to weight ratio, but it also allows the use of a separate internal sealed enclosure providing the load cell's electronic components with NEMA6 or IP67 environmental protection even with the battery cover plate missing, making this industry compact dynamometer even more suitable for use in the harshest industrial or leisure environments.

The BlueLink is powered by four x standard AA alkaline batteries that provide in excess of 500 hours transmission time and its internal antennae ensures loads to an accuracy of 0.1% FS are transmitted safely.

APPLICATIONS

- Versatile for any application to replace outdated mechanical products still in the field.

- Small to medium crane lifts

- Freight and cargo weighing

- Aircraft and marine vessel manufacturing/building

- Cable/rope tensioning

- Precision field testing of chain, rope, wire.

- Multiple applications within construction, transportation and logistics, and material handling

Vetec V-LINK Dynamometer, IP67

The V-LINK Dynamometer from Vetec A/S is designed with the purpose to increase efficiency and accuracy in all situations, including harsh and humid environments.

The development has been focused on optimizing features that make it easy for the operator to handle and operate the dynamometer and still achieve stable and accurate measurements. The increased ease of use is achieved, for example, by a flat design, simple menu structure, quick guide and fast charging with standard USB charger.

Achieving an IP67 class has been especially important in order to accommodate customers working in wet and humid environments. To test the functionality, the dynamometer has been immersed in 1 meter deep water for half an hour. The result was a fully functional product.

V-LINK is designed and manufactured in Denmark for high quality assurance and the service department provides professional support, repair and calibration service.

Utilcell PIN Load Cell Self-Customized

Utilcell (Spain) - PIN Load Cells are frequently used to replace existing axles to turn them into weighing axles, as for example, in cranes. Although they are very useful in those cases where conventional load cells are not fitting anymore, and a custom-made solution is the best option.

You can configure your Load PIN directly through our Online Tool under your specific requirements and receive a fast and competitive quotation. This easy and intuitive tool allows to fulfil all the specifications for your Utilcell Load PIN to speed up the initial phase of the process of product configuration, quotation and production process ending up with fast delivery terms.

Including the UTILCELL’s load PIN into your machinery brings many benefits as:

- Weighing control, limitation and monitoring of overloads.

- Preventive maintenance actions for safety and reducing costs.

- 100% compatible with your existing axles.

- Easy to replace and install with no systems modifications.

- Robust construction in high strength stainless steel.

The Load PIN it is an extraordinary product being able to adapt to many different environments and application requirements:

- Standard output signal directly from the strain gauges in mV/V, as the amplified signal conditioner 4/20mA integrated.

- For potential explosive atmospheres (ATEX) zones 0, 1 and 2 (gas) and 20, 21 and 22 (dust).

- Ingress Protection: IP66 or IP68.

- Working temperatures from 20ºC to +90ºC (4ºF to +194ºF). Available up to +180ºC (356ºF) for high temperature environments.

- Fast delivery terms.

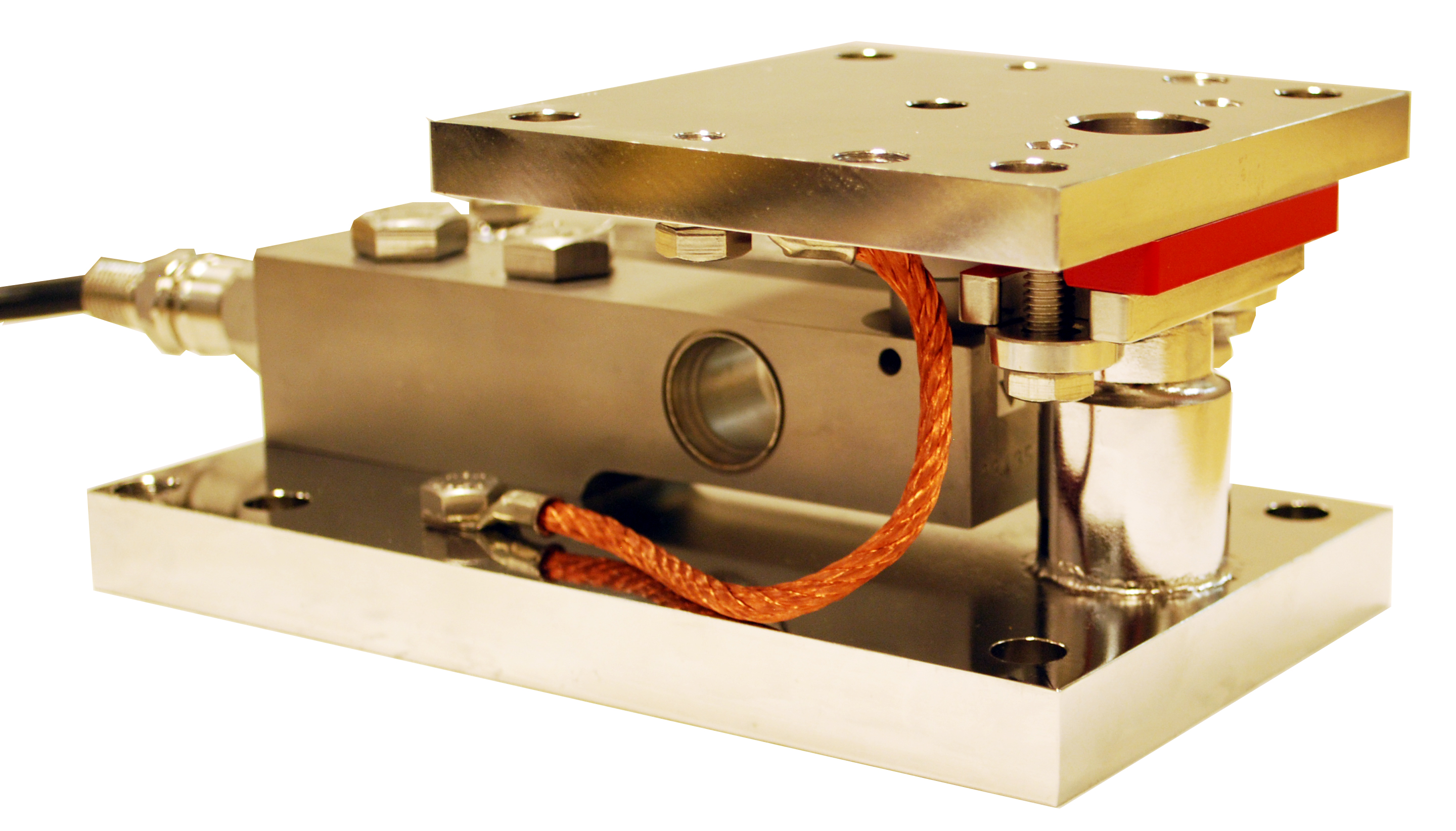

Minebea Intec Weighing module Novego®

The weighing module Novego® was specifically developed to meet the increasingly stringent requirements of the food industry. This hygienic all-in-one solution boasts a range of innovative properties to ensure simple, error-free installation and maximum resistance to lateral forces.

- Hygienic weighing module ensures efficient cleaning

- High degree of process reliability and precision thanks to the innovative side-force-resistant system

- Quick and easy commissioning due to smart add-on parts

- Durable, reliable weighing solution with excellent corrosion resistance

Hardy OneMount™

Hardy OneMount™ Load Cells

The Hardy OneMount™with Advantage® shear beams are specifically built to save customers time and money during installation, calibration, and maintenance. Each load point provides extraordinary flexibility and durability in most industrial environments. Each feature of the load point was intentionally designed based on nearly 100 years of process weighing experience, delivering a best-in-class measurement system for vessel, hopper and tank weighing.

Accuracy

- Self-centering rocker design maintains alignment under considerable shear forces

- Precision sensor (combined error 0.02% rated output) from 1,125 lbs – 22,500 lbs

- Optional Dynamic Stabilization Rods can be purchased to reduce vibration noise on the sensor for better resolution

Safety

- Liftoff and side force ratings are confirmed by third party destructive testing

- True glass-to-metal hermetically sealed sensors deliver the ultimate washdown protection (IP68/IP69K)

- C2® electronic calibration reduces the risk of accidents or contamination from test weights

Easy Installation

- Integral spacers can carry the full rated capacity without the load cell installed, eliminating the need for expensive dummy load cells or welding fixtures

- Once mounts are installed, the load cells slide into place. With minimal tank jacking (1/8”), the spacers are removed for a live load point

- 360° checking mechanism means load points can be installed in any direction

- C2® electronic calibration for fast startup in high capacity installations

Easy Maintenance

- Replace load cells with minimal tank jacking (1/8”)

- Matched mV/V/ohm load cells are easy to replace without recalibration

User Benefits

- OEE improvement from consistent, accurate performance, and reduced installation and maintenance time

- Reduced capital investment and labor typically associated with dummy load cells and welding fixtures

- Reduced complexity of system selection and installation from a single, universal design

See Our YouTube Video on the Safe, EASY and Accurate OneMount!

Easy Installation Process

- Align and level the mounts under the vessel without the load cells installed. The mounts can be installed in any orientation, because of a 360º checking mechanism to ensure accuracy and safety.

- Lower the vessel onto the mounts and weld or bolt the mounts to the foundation and the vessel.

- Perform any peripheral pipe welding or add any required attachments.

- Slide the load cell into place and fasten to the bottom plate.

- Jack the vessel up 1/8” to remove the shipping/installation bracket.

- Lower the vessel onto the live load point and calibrate using Hardy’s C2® electronic calibration.

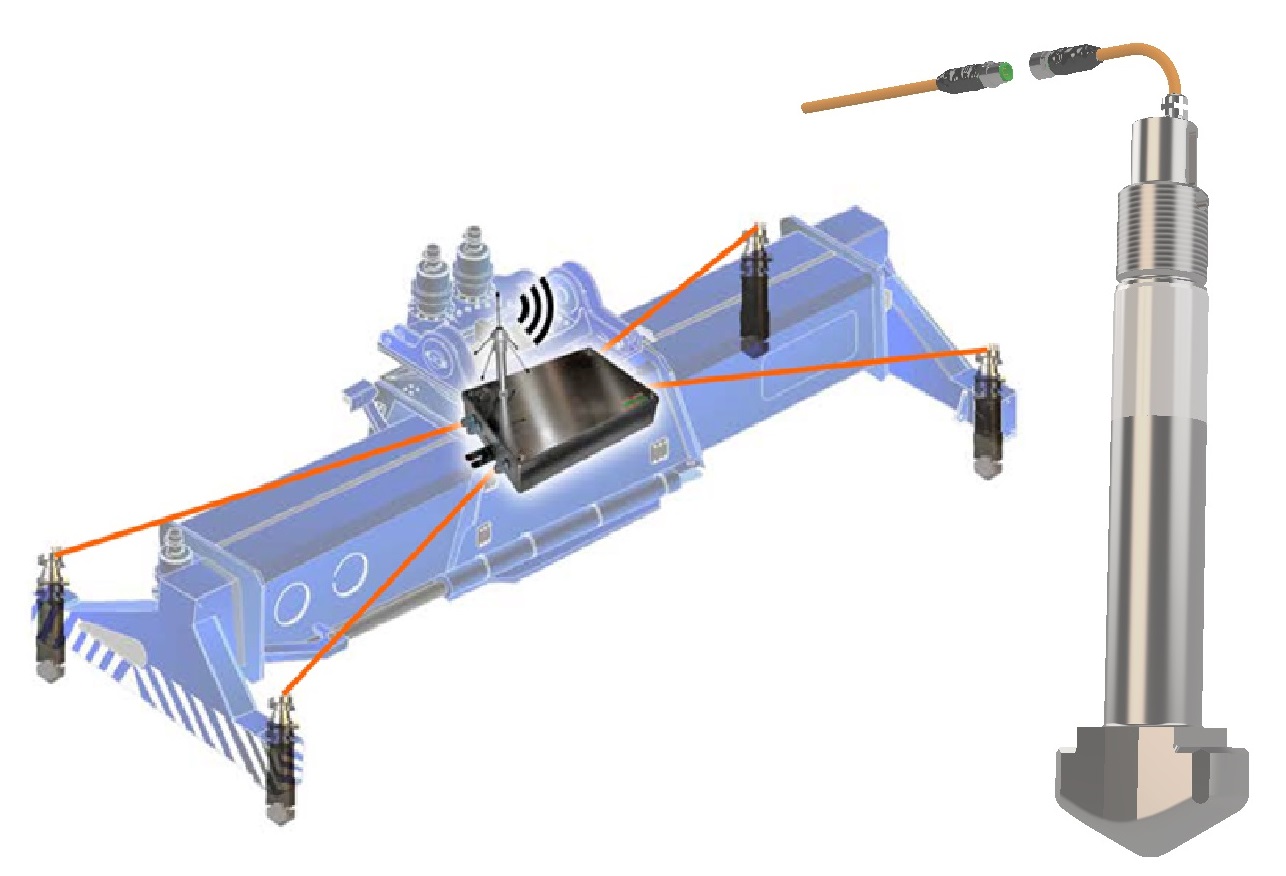

Sensocar TW-D: Twislock Load cell for Container Weight Verification System

Load cell designed to be part of a weighing solution adapted to easily obtain gross mass of containers to

accomplish with SOLAS regulation

- Designed to replace the existing twistlock pieces of spreaders by load cells mechanical compatible with them to easily obtain the weight of containers in motion.

- Digital load cells with open protocol RS485 Modbus.

- High accuracy 3000e C3 OIML Certified (Certificate Nº E-16.02.C02).

- System calibrated from factory. Minimal installation required. No calibration in the field needed INSTALL & WEIGHT (Plug & Weigh System)

- Monitoring of weight of individual load cell to be able to capture alerts of overweight or decentered load.

- Tensile test break at 180t (Report Nº 18/31705078)

- The typical weighing kit Includes 4 TWISTLOCK load cells + Junction box + Weighing indicator (available wired or wireless connection between the junction box and indicator)

Baykon Digital Load Cell

Why Digital Load Cell?

The load cell detecting the load and transforming it into an electrical signal is the core of an electronic scale.

Digital technology revolution has been experienced in the electronics technology since the 1970s. With higher quality, reliability and powerful functions, modern technology's programmable smart products supersede old analogue technology products.

BAYKON digital load cell weighing systems have technological and structural features fundamentally changing the measurement accuracy, weighing accuracy and maintenance performance of electronic scales.

Expectations of an industrial business using electronic scale;

- Minimizing raw material or product losses with high precision and always accurate weighing performance

- Having a scale that does not break down or eliminating possible failures with minimum time and cost

- Having a reliable, quality and traceable scale without paying more than necessary.

- An available system that is open for improvement in more advanced technology investments of the business

BAYKON digital load cells and weighing instruments, a new generation of software and hardware products from the main components of Industry 4.0 age, have been designed to meet all expectations with over 30 years experience of BAYKON, an industry leader in industrial weighing.

Fast maintenance, more precision, higher confidence…

BAYKON new generation digital load cells are designed for quick maintenance, more precision, higher confidence in weighing applications. They have high protection structures and intelligent microprocessors integrated into them and represent the latest in weighing technology, high accuracy and reliability along. With its stainless steel, IP68 hermetically sealed enclosure, it can be used safely in harsh environments. BAYKON digital load cells; eliminate possible errors which can occur with standard analogue load cell scales such as temperature,nonlinearity, hysteresis, electromagnetic effects and voltage variation. Weighing is blocked in case of load cell is broken. Its advanced electronic design provide high resolution and long term stable digital output signal for accurate and reliable measurement. BAYKON digital load cells are matched at the production which provides direct replacement without calibration with test weights for non-legal scales.

Baykon digital load cells advantages:

- Highest Accuracy: Higher sensitivity than analog load cells with In-built hybrid processor

- Rust & Corrosion: The fully welded stainless steel structure, hermetically sealed, IP68 protection class

- Heavy-duty And Water Resist Cables: Dual core cable, creates a protective shield protected by braided stainless steel sheathing

- Eliminated Spoiling Influences: Operation Temperature & Voltage variation, Radio and Electromagnetic effects

- Lowest Service Costs: Easy and quick fault finding, detects problems and simplifies service

- Electronic Calibration: No manuel corner adjustment ( like trimpot, resistance etc. ) in junction box and high accuracy electronic calibration (without test weights)

- Lightning & Surge Voltage Protection: Standard use with LPK24 Protection & Power Supply Kit for 100-240VAC models

- Preventing Fraud & Cheating: Very difficult to cheat through secure digital BLDC RS 485 communication

- Quick Service: After load cell change, use without re-calibration for non-legal for trade scales

- Advanced Weighing Functions: Operates with intelligent European/OIML approved BAYKON weight indicator or terminals