Weighing Review Awards 2025

Nominated for Best Load Cells

UTILCELL MODEL 350 Shear Beam Load Cell

UTILCELL (Spain) – The load cell Model 350 (300…10.000 kg), together its mounting kits, have been designed for robust and accurate weighing in industrial processes of tanks and hoppers, with multiple advantages:

- Model 350i version: Fully stainless-steel construction. Hermetically sealed with the highest protection degree IP 68 and IP 69K.

- Model 350a/n version: Stainless steel or nickel-plated alloy steel construction. Silicone sealed with IP 66 protection degree.

- Globally used in legal weighing systems. OIML R60 Class C 3.000 divisions and NTEP Class III & IIIL 5.000 and 10.000 multiple cell.

- Highly recommended load cell for any type of tanks and hoppers in industrial weighing applications.

- High repeatability and high accuracy of the weighing values.

- Accessories available in several versions:

- Improved force transmission to the load cell due to a ball-based joint, giving the best accommodation in cases of thermal expansion, structural torsion, and deflection.

- Rubber silent-block for higher impact and vibration protection.

- Load foot for industrial 4-load cell platform scales.

- Superior safety systems for the utmost reliability:

- Easy installation in the tank and hopper supports, with or without the load cell.

- Blockage bolts for transport protection of the load cells.

- Upper plate with conical holes for self-centering.

- Integrated lift-off prevention system.

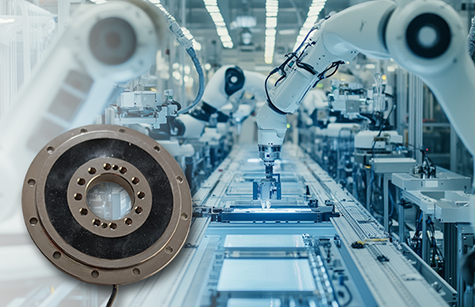

Zemic NB4A Joint Torque Sensor

Zemic has developed a range of high-performance sensors, tailor-made for the robotics industry, that not only improve the precision and reliability of robots but also represents a new leap forward in robot intelligence.

The robotics sensors from Zemic measure forces and weights using strain gauge technology. They are compact, lightweight and highly accurate, making them suitable for integration into complex systems.

The Zemic NB4A Joint Torque Sensor (100 - 210 Nm) is part of a series of joint torque sensors, specifically designed for high-precision applications such as quadruped robots, bipedal robots, and robotic arms.

By providing real-time torque measurements, the NB4A Joint Torque Sensor enables precise and adaptive control. This allows robots to manage complex and dynamic motion paths or execute demanding tasks, such as aligning and assembling, sanding and polishing etc. with ease, delivering a revolutionary level of performance and operational capability.

Characteristics of our NB4A Joint Torque Sensor:

• compact structure, high torque, small size

• suitable for joints in robot

• outstanding performance

• light weight design

• powerful torque

• exceptional strong anti-crosstalk capability (Fz ± 150N) ± 0.1

• excellent temperature performance.

HBK SP4Mi – flexibility and new IO-link interface

Hottinger Brüel & Kjær (HBK) has recently introduced an enhanced version of its SP4M load cell series, now featuring the SP4Mi model equipped with an IO-Link interface. This advancement aims to optimise industrial connectivity and modernise weighing applications.

Versatility and Precision

The SP4M series is celebrated for its compact design and versatility, enabling seamless integration into various systems such as bench, floor, and conveyor scales, as well as filling and production setups.

Constructed from aluminium, these load cells offer weighing capacities ranging from 1 kg to 200 kg and are certified to achieve accuracy up to the C6 Multirange class, boasting an impressive maximum factor (Y value) of up to 20,000. These attributes make them ideal for diverse sectors, including the food, packaging, chemical industries, trade, and agriculture.

Digitalisation and Automation

The SP4Mi model, featuring an IO-Link interface, is specifically designed for companies aiming to digitise and automate their weighing processes. Its intelligent functions encompass data preprocessing, real-time monitoring, and maintenance alerts, thereby reducing downtime and repair costs. Fully compatible with existing IO-Link systems, the SP4Mi facilitates seamless integration, modernising current industrial setups.

Additional Features

The SP4M/SP4Mi load cells offer customisable options, including tailored cable lengths, balanced output for parallel connections, and explosion-proof versions, ensuring robustness in demanding and potentially hazardous industrial environments.

Moreover, the SP4Mi incorporates integrated weighing algorithms, granting users access to real-time data, simplifying diagnostics and maintenance, and ensuring smooth integration into common industrial Ethernet-based fieldbus architectures via a 4-pin M12 connector. These advantages assist engineers in accelerating time-to-market while enhancing product quality.