Weighing Review Awards 2018

Nominated for Best Onboard Weighing Systems

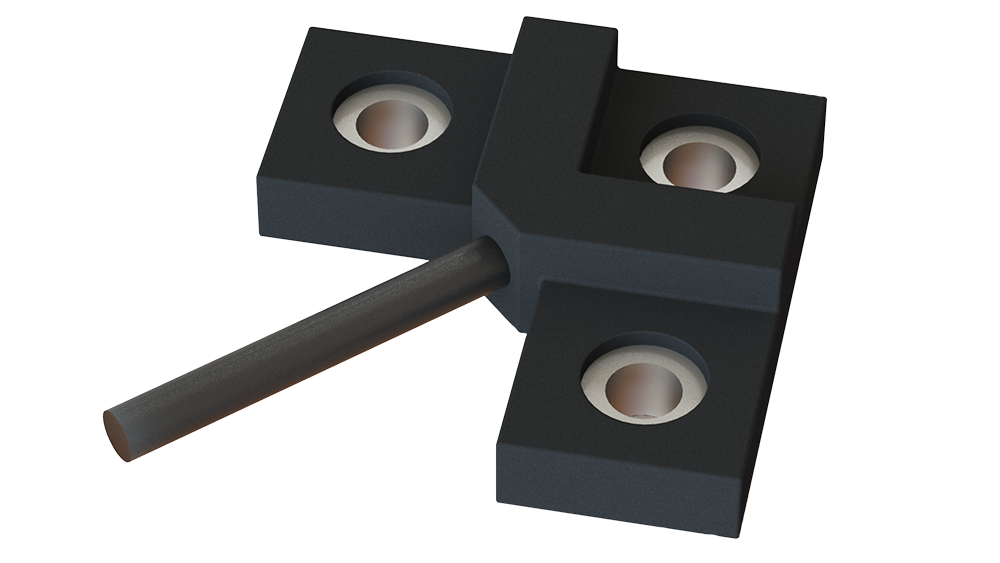

UTILCELL Customized Load Pin

The UTILCELL’s load PIN is specially designed for replacing and upgrading existing axles and provide reliable measurements of loads applied on the same axis.

Including the UTILCELL’s load PIN brings many benefits as:

- ATEX version available Zone 01-2 and 20-21-22.

- Weighing control, limitation and monitoring of overloads.

- Preventive maintenance actions for safety and reducing costs.

- 100% compatible with your existing axles.

- Easy to replace and install with no systems modifications.

- Immediate quotation and fast delivery terms including customized detailed drawings and fulltechnical specifications.

- Robust construction in high strength stainless steel.

- Standard: IP 66 protection. Optionally: IP 68 and ATEX.

- Working temperature from 20 oC to +90 ºC and high temperature up to +180 ºC.

Air-Weigh LoadMaxx for Tractors

Tractor scales display accurate weight information for both air and mechanical suspensions on a convenient in-dash display. The Bluetooth capabilities of LoadMaxx allow the scale to be paired with the LoadMaxx app, turning any Smart device into a scale display. Other communication capabilities include the ability to transmit weights back to the home office via the tractor’s data bus through a third party on-board computer.

The LoadMaxx Tractor Scale will automatically display trailer weight data from LoadMaxx-equipped trailers. No special tractor/trailer connection is necessary because trailer weight data is multiplexed over the vehicle’s existing 7 way. The LoadMaxx scale is a true drop and hook system, allowing trailer weights to be displayed automatically in cab without driver intervention. LoadMaxx also supports an optional in-cab printer for instant weight receipts.

Features:

- Measures steer and drive axle group weights, Gross Vehicle Weight (GVW), and Net Payload

- Supports air ride and most mechanical suspensions

- Dual point calibration – empty and fully loaded

- Pin protected settings

Advanced Communication Features:

- Bluetooth communication to LoadMaxx App

- Reads and displays weight of LoadMaxx trailers equipped with ComLink

- Ability to transmit weights to tractor’s data bus

Datum Electronics Bolt-On Strain gauge Sensors

Datum Electronics Ltd.’s Bolt-On Strain Gauge sensors, are a solution to many strain measurement, weighing and load applications where quick, simple, highly robust and repeatable installation is the key.

Extremely reliable and rugged in design, they remove any need for highly skilled strain gauge expertise, No Gauge adhesives required, soldering, complex wiring and worry regarding environmental protection for the harshest of environments, even underwater!

Main advantages include:

- Simple installation on a production line, or retro fitted

- Quick and easy to install without any fine wiring or soldering, it simply bolts in position

- Robust design allows the sensor to work in almost any environment, in any weather and even underwater

- No disruption to the structure or struggle to find a way to install sensors in-line or cut into the structure (E.g. Silo weight measurement applications, no need for a load cell)

- No complicated glue/adhesives procedures

- No complex cleaning and installation process for strain measurement

- Resistant to chemicals including: Dust, Water, Salt Spray, Urine, Paint, Dilute Acid Fuels: Diesel, Gasoline, Bio Diesel Oils: Lubricating, Hydraulic Coolant: Ethylene Glycol, Coolant Conditioner, Freon

- Highly precise and repeatable data measurement

- Basics outputs available as standard for full bridge strain gauge outputs, “off the shelf”

- Can be tailored for high volume applications to suit your needs

- Versions available for conditioned/amplified outputs

With ever increasing legislation, measuring load & weight in real time has become a real priority for a number of applications across various industries, covering automotive, marine, inventory control, process & handling, to name just a few.

Some typical applications of Datum bolt-on sensors, successfully deployed in the past few years include:

- Vehicle load measurement on a huge variety of Heavy off Road machinery, Trucks, Lorries, telehandlers/forklifts and Agricultural vehicles.

- Vehicle Tilt alarms, for telehandlers, by sensing axle load and bending during the load and extension or operation of the booms.

- Dynamic monitoring for structures and processes in Oil production

- Hoppers/Storage/Silo weight and load measurement, where it isn’t possible to install expensive load cells, requiring alteration to the Silo structure by modifying the legs and supporting structures.

- Bridges and structures of all types

- Oi rigs, and many many more.

Their ability to be mass produced for customers requiring an OEM solution for their application, means you can have a sensor tailored for your requirements, supplied in volumes to suit your schedules. Furthermore, standard bolt-on strain gauge sensors are available off the shelf meaning they can be delivered to you on short lead times.

Simply Install and forget!

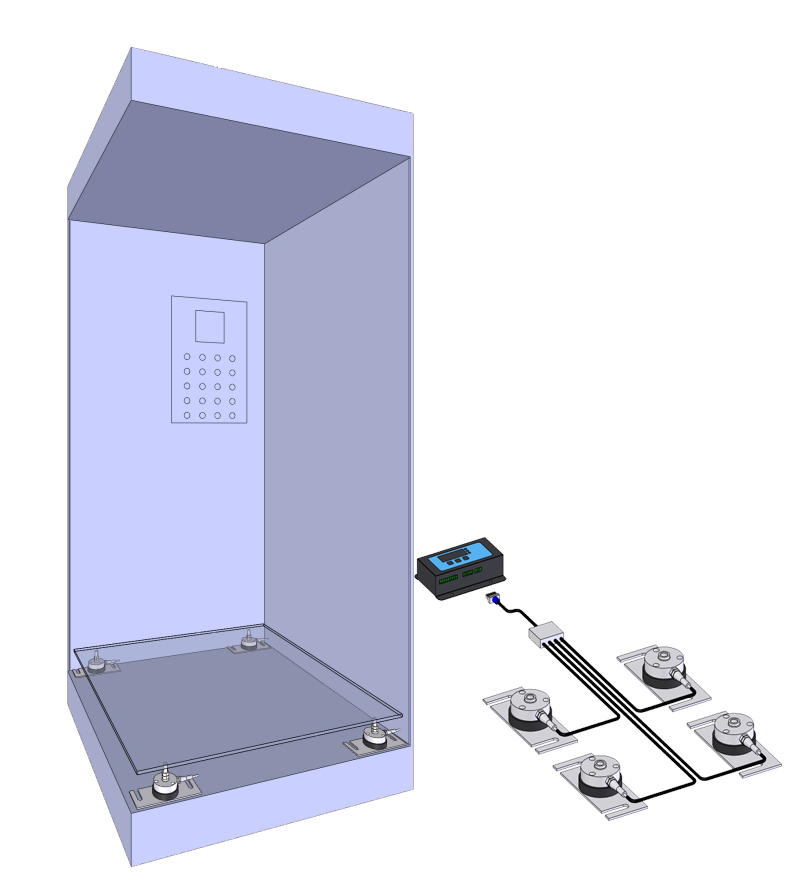

Zemic Europe Elevator weighing kits

Best weighing solution: Zemic Europe elevator weighing kits

The engineering teams at Zemic worked together with key elevator manufacturers to develop a new and innovative solution for elevator overload protection. The elevator manufacturers indicated that overload is a main feature, however it would be more optimized when this could be combined with topics such as energy saving motor management and child protection.

Besides functional requirements our engineering teams were challenged by specific product demands such as shape of the loadcell, installation requirements and specific market requirements.

Zemic introduced 3 weighing kits based on 3 different ways lift / elevator companies are measuring the weight. We offer complete solutions to measure the weight under the cabin, under the cable springs and into the cable springs.

Our "Elevator Weighing System: Cabin" has the following important features:

- Indicates when elevator is loaded to 90%.

- Determines if the elevator is overloaded.

- When less than 15kg, the elevator doesn't move (child protection).

- Adjusts engine power required to actual weight.

Our Headoffice in Europe is based in The Netherlands from where we stock thousands of products which can be delivered within 1 day to anywhere in Europe.

LOADRITE L3180 SmartScale for Wheel Loaders

The LOADRITE L3180 SmartScale is the next generation of onboard weighing that uses weighing intelligence for more accurate, precise and faster loading. It also connects machines and devices for the collection and syncing of loading data.

Video: https://youtu.be/Jbx6NiMrTMk

Features:

- Weighing intelligence adjusting for rough terrain, technique, and machine movement for with greater accuracy, precision and speed.

- Greater loading accuracy

- New multi-axis solid-state IMU sensors

- In-cab performance KPIs (ton/hour, tons, truck count), production metrics (ton/product) and Productive Time Tracking (time/product, time/task)

- Data caching during power or signal weakness/loss

- Loading location heatmap to monitor incorrect stockpile or truck loading

- Built-in WiFi and GPS

- 5.7” color touch screen

- eTicket sends load tickets via email

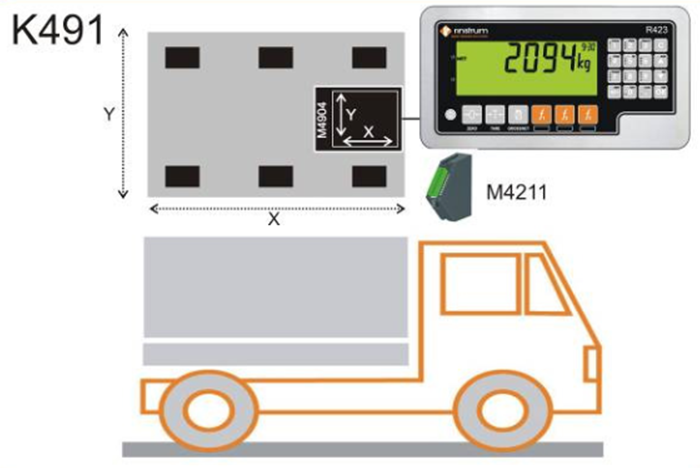

Rinstrum R400 Series K491 Tilt-Compensating Indicator

Rinstrum’s R400 Series K491 indicator uses an accessory module to connect to a 2-axis tilt sensor that provides tilt compensation. Both variants - the R420-K491 and the stainless steel R423-K491 are ideal for panel-mounting in specialist truck OEMs that require electronics for accurate load weighing solutions where the load may be on an angle. The main application is for a truck to have accurate weight readings, compensating for uneven surfaces where a weight reading might be taken.