Weighing Review Awards 2020

Nominated for Best Train Scales/Weighbridges

IVM s.r.l. POWERVE - POrtable WEigher for Railway VEhicles

POWERVE (POrtable WEigher for Railway VEhicles) is an innovative hand-portable weighing system, able to determine how the weight force of a rolling stock is distributed on each wheel. More than just a weighing equipment, POWERVE can be considered a safety equipment for the railway industry, being able to instantly measure the rolling stock's vertical wheel force distribution, detecting potential unbalancing issues. It is so a precious equipment which allows to prevent the derailment risk.

One of most interesting system’s feature, is its capability of directly measure the same balance that the rolling stock has on a straight and leveled track, by measuring at the wheel/rail interface (so where the wheels load on the rails) and not on other commonly used points, different by the wheel/rail interface, which can deliver different results on the distribution of the vertical wheel forces of a rolling stock.

POWERVE is also already in line with the latest requirements of the EN 15654-2:2019 “Railway applications. Measurement of vertical forces on wheels and wheelsets. Test in workshop for new, modified and maintained vehicles”

POWERVE is the ideal solution for:

- Commissioning of new rolling stock or post-revamping rolling stock

- Derailment prevention

- Derailment investigations

- Workshop or in-field maintenance

- Balancing suspensions

- Verification of the set-up of the rolling stock by measuring the distribution of the wheel’s vertical forces

- Installation of new equipment (e.g. on On-Track-Machines)

- Verification of the distribution of the vertical forces due to non-uniform wear of the wheel diameters or faulty suspensions.

- Verification of the distribution of the transported cargo

Main Features:

- It improves the rolling stock running safety, because it allows to measure the true distribution of wheel vertical forces on track, by measuring at the wheel/rail interface and in running order conditions, without modifying the natural status of the rolling stock suspensions, as on the track

- To properly perform these measurements on a rolling stock, several operational errors must be taken into account. In our case, not only the accuracy of the sensing elements has been certified (Load Cells Class II according to ISO 376), but also the whole measurement accuracy performed in field (<1% certified by a Notified Body)

- Hand-transportable everywhere, also by airplane (25 kg for Wheelset Kit split in 2 cases) - Heaviest single part of just 7kg

- Capable of measuring from 2 to 6 wheelsets at the same time (POW2X to POW6X)

- Already in line with the latest EN 15654-2:2019 requirements

- User friendly control SW on Tablet, that automatically generates reports in pdf format, equipped with Cloud technology to allow an easy management of the performed measurements (and to get data also in other formats, Excel, CSV, etc)

- Easy to install in few minutes, and the installation does not require mechanical fixings procedure. Moreover does not require any spacer in order to balance the system on the same plane of the track

- Battery powered with 10 working hours battery life – MicroUSB rechargeable

- Track gauge independent

- Equipped with several check controls during the measurement, both HW/SW, in order to perform human indipendent results. During the procedure the system asks to perform 4 measuring cycles as minimum. In case of too much difference between the measured values, the system automatically asks to perform more measurement cycles to ensure the certified accuracy results

- It weighs the rolling stock in self equilibrium condition, without the need of stopping the train on the system, inducing possible errors due to brake force reactions

- Useful to set the suspensions, in order to re-distribute the vertical forces when necessary

- The measurement procedure needs to move the rolling stock of just 1 meter during the measurements, so it is perfect also for small workshops

- Weighing range of 15 tons per wheel / 30 tons per axle

- Identification of rolling stock also by means of photographs and their storage

- Wireless communication between devices and with the Tablet Management System

- Data Transmission - Wifi/Bluetooth

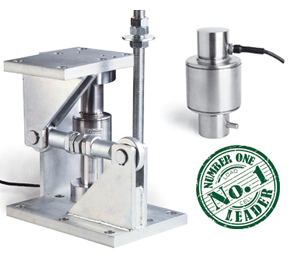

UTILCELL Model 740 Compression Load Cell

The model 740 is a rocker pin compression load cell specially designed for train and weighbridge scales and high capacity weighing systems. With more than 15 years in the market and more than 400.000 units installed is our number 1 in sales in the European market.

Its main characteristics are:

- Wide range of capacities from 15t to 600t.

- Totally stainless steel construction and hermetically welded.

- Ingress Protection class IP 68 and IP 69K.

- Lightning protection with surge arresters.

- Individual calibration in force machine with optimized precorner adjustment.

- Adapted to extreme climates, with temperature working limits from ‐50°C to +80°C.

- Globally certified: OIML, NTEP, CE, ATEX, FM, IECEx.

- 36 months guarantee, including lighting strikes.