Höfelmeyer Waagen GmbH (Germany) – Production processes are becoming increasingly complex, digital and transparent. Only by using optimally coordinated process steps, components, interfaces and QA measures can consistently high production quality be ensured. This applies to food production as much as for the chemical, pharmaceutical, cosmetics, plastics, and bulk materials industries, etc.

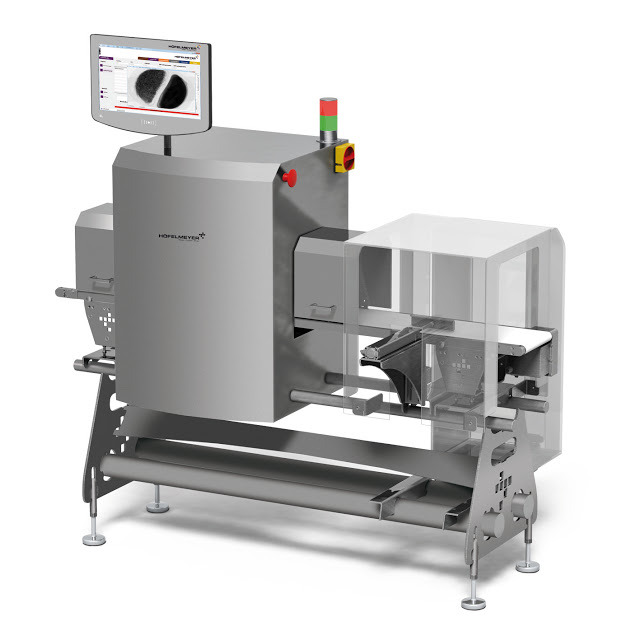

An important pillar of quality assurance is early and reliable management of contaminants. The X-ray system from Höfelmeyer Waagen GmbH plays a vital role in achieving this. The X-ray scanner is used, for example, for foods, granulates and liquids. With a sensor resolution of 0.8 mm, the scanner detects a wide variety of contaminants. Examples include metal, glass, ceramics, stone, bone and several plastics (PVC, rubber, Teflon, etc.). It also detects product defects such as tears, air bubbles, cracks or clumping and checks attributes like completeness, filling quantity, weight and position. Even products in metallic packaging can be reliably checked. All products that do not comply with the requirements are automatically ejected from the line by separating systems including pushers, air nozzles and sorting gates.

In real-time operation, the system enables high-speed inspection at a rate of up to 600 pcs/min. The product-specific visualization software incorporates simple, fully automatic product learning. It is also possible to hide packaging components (aluminum clips, etc.). The data is centrally stored and reused for the monitoring, documentation and optimization of production.

With its modular structure, the X-ray scanner enables single-lane, multi-lane and multi-product checks and is very simple and intuitive to operate. It features a cleaning- and maintenance-friendly design in accordance with hygienic design requirements and complies with BRC, IFC and HACCP standards.

To ensure the best possible product quality, safety and process efficiency, however, the crucial factor is where and in which combination X-ray inspection systems are used. Multi-stage checks are usually a practical solution. As a weighing and process specialist, Höfelmeyer provides comprehensive advice and supplies QA solutions for the whole production process. Its portfolio therefore includes metal detection, optical detection, weight checks, labeling, leak checks, separation, etc. These components can be integrated into the existing production line in a modular format, or they can serve as a complete QA station with a central control system for comprehensive safety. External systems can also be integrated into the QA station. The advantage of having a central QA partner for the customer is comprehensive service, fast response times and the provision of all services from a single source.

This website uses cookies. By browsing our website you accept the use of cookies. For more information read our Terms of Use.

Top production quality thanks to an optimally embedded X-ray Inspection from Höfelmeyer Waagen

- By Hoefelmeyer Waagen GmbH

- Posted on Nov 13, 2017

For more information about this article from Hoefelmeyer Waagen GmbH click here.

Other articles from Hoefelmeyer Waagen GmbH.

Interesting Links:

List all your Scales and other Weighing Products (new and used) on our Marketplace !

Visit AutomationInside.com for Automation and Technology Related News!

Are you interested to include your Link here, visible on all WeighingReview.com articles and marketplace product pages? Contact us

List all your Scales and other Weighing Products (new and used) on our Marketplace !

Visit AutomationInside.com for Automation and Technology Related News!

Are you interested to include your Link here, visible on all WeighingReview.com articles and marketplace product pages? Contact us

© Hoefelmeyer Waagen GmbH / International Weighing Review

Previous article

Mettler-Toledo's X37 Series Combines High Detection Sensitivity with Lower Power Consumption

Next article

Dynamic Check Weighing Machine on The Connected Enterprise™ Helps Prevent Overfilling Expense

Popular News

Weighing Review Newsletter

Popular Tags

Login

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.