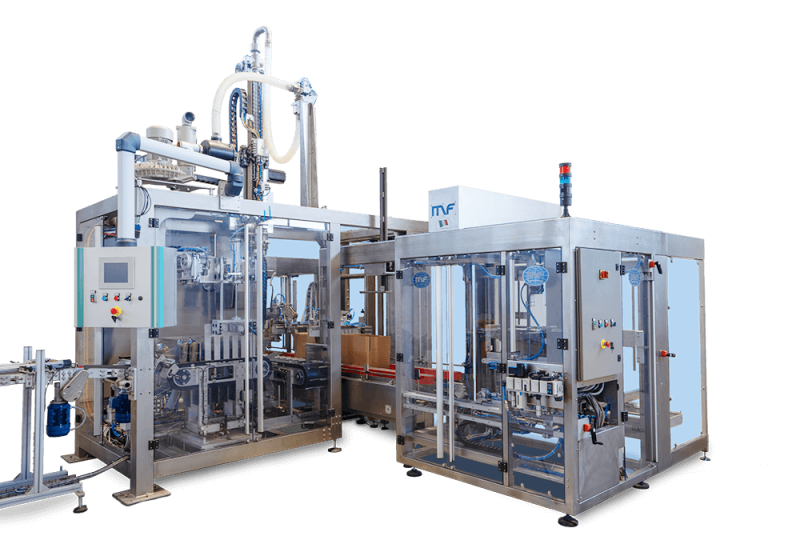

MF TECNO (Croatia) - Packaging system for cereals: Conveyor belt, multi-head weigher, VFFS packaging machine, and case packer.

This project we designed and manufactured for our customer in Croatia was a complete system for packaging Cereals.

It is a complete solution for packing cereals and polenta in 1 Kg bags, at high production levels.

To maintain high speed in the packing phase we decided to include a packaging machine with continuous motion.

Weighing and Conveying system:

We start with a big bag unloading device which leads the product to a vibrating channel. From there the product enters the belt conveyor that feeds the multi-head weighing machine.

The multi-head weighing system is the perfect solution for small bags and fast production, considering its speed and high precision.

Packaging Machine:

The Vertical packaging machine our customer chose for this project was the MF 52 SPEEDY.

The MF 52 Speedy, is a vertical form fill and seal machine that can pack up to 4800 bags per minute, thanks to the continuous motion.

After the bags are filled, they pass through a metal detector. This is a necessary step, considering we are talking about a food product it is very important not to have any metal residuals inside the bags.

Bag transporting and Case Packing Machine:

Our customer decided to opt for a double choice after the packing machine. The bags can go towards the case packing machine or in a turntable, to be later collected by an operator.

Our case packing machine creates American boxes, loading from the top.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.