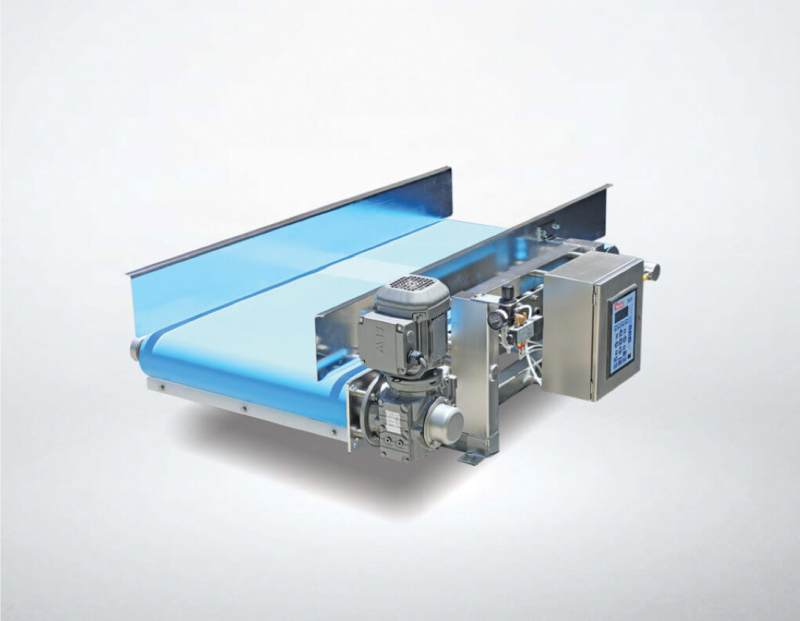

Thayer Scale-Hyer Industries, Inc. (United States) - The Thayer Scale MWF-OS Sanitary Open Construction Weigh Belt Feeder provides accuracy, ruggedness, and reliability. For seventy years leading food processors have been using Thayer Scale weigh belt feeders to process potato and tortilla chips, pet food, cereal, pasta and more. Major food brands rely on the MWF-OS weigh belt feeder for exceptional stability, high flexibility and performance.

The MWF-OS self-cleaning pulley eliminates material build-up and belt tracking problems. Unique flared skirt design prevents material spillage and assures proper feed control. Rigid scale support system provides exceptional stability, assuring accuracy without frequent re-calibration.

A standard design coupled with dimensions and rates that are tailored to each application add versatility to its capabilities. Its design for ease of maintenance and the ability to change its throughput rating gives it a long useful life in a rapidly changing industrial environment.

Features:

- Handles a wide range of materials and densities

- Sanitary, stainless construction

- Unique belt tracking system assures positive tracking without the use of mechanical devices

- Easy access, low maintenance design, no tools disassembly

- Excellent accuracy and stability

- Rugged construction-built to survive

- Cantilevered frame for fast belt removal

Slack belt design for more stable accuracy:

The MWF-OS belt is driven from the head pulley located at the outlet end of the feeder, rather than the tail pulley located at the end inlet. This permits lower belt tension during operation for better sensitivity and more stable accuracy. The head pulley is crowned to prevent belt tracking problems and is sheathed in rubber lagging to prevent belt slippage.

Speed sensor mounted at idling tail pulley:

Measures the true speed of the belt via rotation of the idling pulley, not an inferred belt speed based on motor speed. Belt slippage or breakage is immediately detected because the idling pulley stops rotating.

Automatic calibration:

Thayer Scale’s optional automatic test weight mechanism provides a means for applying a precision test weight to allow completely automatic calibration. The calibration sequence can be initiated via the weigh belt instrument keypad or via a contact closure. The need for test chains is eliminated.

Full length adjustable skirt boards:

Tapered and flared from the inlet to the discharge to prevent pinching of material between the skirt and the belt. Skirt boards are located inside the belt flanges to provide two barriers to contain material and prevent spillage.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.