Minebea Intec (Germany) - Press Release: New weighing and inspection solutions for more efficient production.

Minebea Intec, a major manufacturer of weighing and inspection technologies, will be presenting its products and innovations at interpack 2023. The company will be attending the leading trade fair for the packaging industry from 4 to 10 May and presenting its solutions which help manufacturers to increase their product safety and efficiency. With systems for visual product inspection, like the VisioPointer®, through to a new checkweigher, the company is expecting to generate a lot of interest. The checkweigher Flexus®, which is also available as a high-speed version, will be on display along with the X-ray inspection system Dylight. These products, which together formulate a complete efficient production process, will be on show for attendees to discover the range of features on offer. Visitors to the stand will also be able to see the company’s established, high-precision products live alongside new innovations. This includes the automatic weigh price labeller WPL-A, which provides a complete package for customers in the food industry.

These days, flexible and efficient production processes are digital and interconnected. However, face-to-face interaction is now firmly back on the agenda and Minebea Intec is looking forward to taking advantage of this opportunity at interpack after a six-year hiatus due to the coronavirus crisis. Industry 4.0 is a key focus and with its smart weighing and inspection technologies, the Hamburg-based company provides optimal solutions to take production lines to a whole new level. This means that Minebea Intec’s products are perfectly aligned with the key topics at interpack 2023, which will be focusing on the best possible performance,

sustainability and digitalisation. From checkweighers, metal detectors, and X-ray inspection systems, to platform scales and the applicable software solutions, through to the new automated image processing technology: visitors to Minebea Intec’s stand at the trade fair can look forward to expert advice to help make their production processes even more efficient.

Optical inspection for quality assurance of packaged products:

With its new range of vision systems, Minebea Intec is adding a fourth pillar of quality assurance products in the form of a range of end-of-line inspection devices. Those who visit the stand at interpack 2023 will be able to experience the VisioPointer® live. With three cameras as standard, multiple lighting options and optional side and satellite cameras for multi-angle inspection, the product delivers high-precision results when checking labels, print or the expiry date. It also provides reliable seal inspection. This is an extremely important visual quality check in the food industry, as the product’s expiry date is only valid if the packaging is absolutely leak-tight. “The seal inspection is performed by cameras and

is fast, non-destructive and configurable,” says Dr Thorsten Vollborn, Senior Product Management for Product Inspection at Minebea Intec. “Conventional methods do not offer these advantages. We are proud to now be able to integrate this outstanding solution into our customers’ production processes.” The machine is also capable of product inspection such as bruising and blood spots in salmon, bread bake colouration and dimensioning, and shape recognition for products like biscuits in variety packs. For hard to see applications, hyperspectral cameras can be used to distinguish between products.

Automatic weigh price labeller saves time and space:

Alongside this new inspection technology, Minebea Intec will also be sharing its expertise and experience from over 150 years in industrial weighing with visitors to its stand at the trade fair. Before products are sent for shipping, they often need to be labelled in some way. The automatic weigh price labeller WPL-A is a reliable solution for products which have variable weights such as cheese, meat or fish. This not only facilitates product tracing, it also increases throughput and productivity. The WPL-A meets directives and standards such as the Measuring Instruments Directive (MID) and the National Type Evaluation Program (NTEP) of the National Conference on Weights and Measures (NCWM). The system is produced in Europe to the highest quality standards and offers maximum modularity and connectivity. The device is the ideal au-

tomatic labelling system and can be configured to individual requirements to meet all kinds of challenges.

Checkweighers: easy operation combined with high-resolution weighing technology:

In the checkweigher range, Minebea Intec will be presenting its Essentus® Performance L Combi, the latest version of one of its best-sellers. The innovative design combines the checkweigher Essentus® Performance L and the metal detector Vistus® in one base frame. This makes the system extremely compact and highly efficient. The combi system is used to check weights, perform integrity checking, control upstream filling systems, and check for metallic foreign objects at the same time. The Essentus® Performance L Combi is also verifiable and features a stainless steel conveyor system, which is ideal for meeting hygienic requirements, particularly for wet applications or unpackaged products.

Want to experience the high-quality Made in Germany weighing and inspection technologies live and benefit from talking to Minebea Intec’s experts? Then we would be delighted to welcome you to Minebea Intec’s stand G73 in hall 11!

Picture 1 Caption:

VisioPointer®: optical inspection for quality assurance of packaged products.

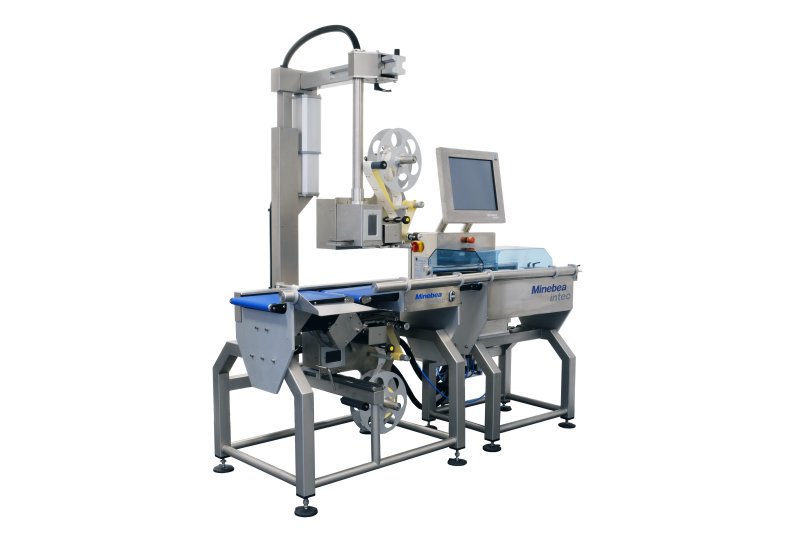

Picture 2 Caption:

The automatic weigh price labeller WPL-A is equipped with reliable software and the latest weighing and printing technology.

Picture 3 Caption:

Checkweigher Flexus®: hygienic design meets flexibility and maximum performance.

About Minebea Intec:

Minebea Intec is a leading manufacturer of industrial weighing and inspection technologies. The Hamburg-based company has been offering products and services which are synonymous with innovation, performance and reliability for more than 150 years. Their product portfolio includes platform scales, load cells, vessel and silo scales, checkweighers, metal detectors, X-ray inspection systems and user-friendly software solutions. Over 1000 employees at 20 locations worldwide help industrial customers to increase the precision and efficiency of their weighing and production processes. A network of over 200 partners in 70 countries completes the sales and service locations of this global player. The unmistakeable premium German Quality is reflected in the brand’s promise ‘the true measure’. Minebea Intec is part of the MinebeaMitsumi Group, one of the leading companies for high-precision production components, such as ball bearings and engines, as well as high-quality electronic components, such as sensors, antennae and IoT solutions. The group, based in Tokyo, has over 87,000 employees worldwide and reported a consolidated net turnover of JPY 1,124,140,000 billion (approx. EUR 7.93 billion) for 2022.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.