The salt is solution-mined, which is a method where fresh water is injected through a pipe into deep shafts that end in the salt beds. The salty water (brine) is drawn up and flash-evaporated on drying screens, which are then scraped and dumped, at 104 °C (220 °F), onto two separate flat belts. The customer was previously using a theoretical calculation to predict the tonnage the flash evaporators produced.

The problem with this was, the theoretical calculation was proving inaccurate for cost control of the production mass balance through the facility. If this theoretical calculation varies even slightly from what was actually being packaged, they could be either shorting their customers, or significantly increasing their costs by over estimating what was being produced.

Solution:

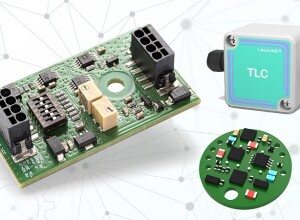

The local Siemens representative recommended the Siemens Milltronics MSI belt scales for monitoring the actual amount of product flowing on the belts. Two of these belt scales (with high temperature load cells), along with Milltronics BW500/L integrators and high temperature, shaft-mounted speed sensors were installed to measure the flash-evaporation production as the very hot salt comes out of the vacuum production on its way to milling and bulk storage.

The Milltronics MSI features an option for high temperature load cells for environments up to 175 ºC (347 ºF).

The SITRANS WS300 was extended away from the conveyor to help with heat dissipation and was also guarded to avoid accidental contact with personnel.

The customer segregated the salt streams, according to the different grades of production requirements: 75% of the hot salt is used to make water softening pellets and cubes, 15% goes into granulated food grade salt, and 5% goes into block salt production for animals. All the finished product production is weighed and accounted for. Then, the customer compares those values to the Siemens belt scale reading for a mass balance comparison.

Now, by using the new Siemens belt scales, the customer knows, with much more accuracy, how much of each grade of salt they are producing.

Benefits:

- Improved process reliability: Now the customer has a much more accurate method of measuring the salt that is being packaged; accuracy of the theoretical calculation was about 15%, while the belt scale accuracy is ± 0.5% or better.

- Local support and service: The customer benefits from the service of a local, experienced field engineer who is able to assist during the set up and installation, and is available for recommendations, programming and material tests.

- Quick and easy setup: The ease and simplicity of programming the Siemens Milltronics BW500/L integrator makes start up trouble-free.

The Milltronics MSI belt scale’s proven use of parallelogram-style load cells results in fast reaction to vertical forces, ensuring instant response to product loading. This enables it to provide outstanding accuracy and repeatability, even with uneven loading and fast belt speeds.

About the Siemens Milltronics BW500/L integrator:

The Milltronics BW500/L integrator is for use in basic belt scale or weigh-belt applications. It operates with a belt scale and a speed sensor. Belt load and speed signals are processed for accurate flow rate and totalized weight of bulk solids.

About the SITRANS WS300 speed sensor:

The SITRANS WS300 speed sensor is a low- to high-resolution, shaft-driven instrument that operates in conjunction with a conveyor belt scale, providing a signal to an integrator which computes the rate of material being conveyed. At only 1.22 kilograms (2.68 lbs), it is one of the lightest and most durable units ever developed for monitoring conveyor belt speed. With its rugged cast aluminum housing, it is suitable for outdoor installation, and its low weight prolongs bearing life.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.