Cooperativa Bilanciai (Italy) - Weighing on rails in ATEX area.

Our solution:

Because of the risk of explosion in the area, specific weighing systems were required for the products coming in on railway cars.

The weighing system was installed in accordance with the atex regulations for explosive atmospheres.

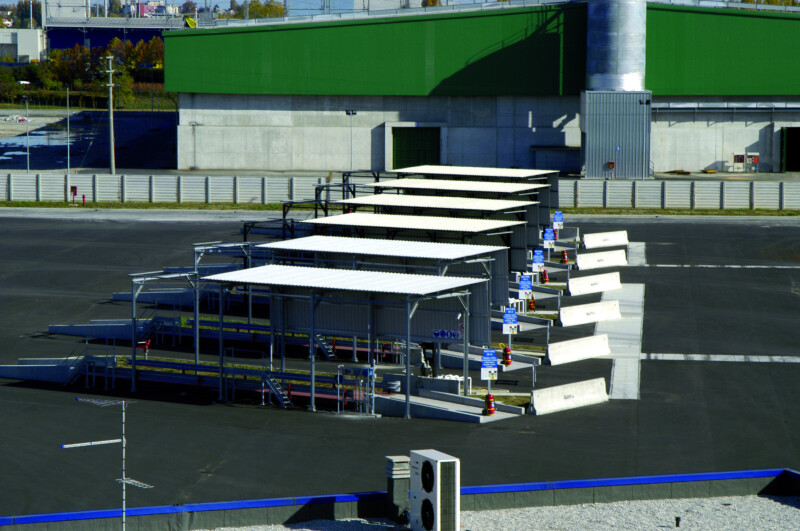

The complete system is composed of 18-metre railway weighing platforms with a capacity of 100 tons, and 16×3-metre road weighing platforms installed above ground and equipped with guardrails with a capacity of 60 tons. In addition, weighing terminals are installed in the control room, and PCs and software allow only one operator to supervise the operations in progress, set the loading operations and issue the relative documents.

The gross, tare and net weighing operations are performed directly at the unloading points without having to move the tankers thus obtaining the value of the quantity of product transported.

The systems also allow performing material loading and shipping operations.

The weighing systems for the outgoing products are positioned directly in the loading bay so that the weighing operations can be performed without having to move the vehicle off the platform.

That way, the quantity of product loaded is predetermined directly from the control room in relation to the type of vehicle and/or customer and the vehicle cannot be overloaded.

The operators can check and control the operations in progress on the display.

All the incoming and outgoing product operations are monitored by a PC on which management software has been installed.

The weighing and automation system guarantees that the data processed complies with the metrological and taxation requirements.

Advantages:

- Weighing directly at the unloading points

- The quantity of product unloaded is controlled directly from the control room

- The systems allow material loading and shipping operations

- The weighing systems for the outgoing products are positioned directly in the loading bay so that the weighing operations can be performed without having to move the vehicle off the platform

- The quantity of product loaded is predetermined directly from the control room in relation to the type of vehicle and/or customer

- Vehicle overloading is avoided

- Display to check and control the operations in progress

- All the incoming and outgoing product operations are monitored by a PC.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.