Weighing Review Awards 2021

Nominated for Best Industrial Scales

Intercomp LS630-WIM™ Low Speed Portable Weigh-In-Motion Scale System

Intercomp’s LS630-WIM™ (Weigh-In-Motion) portable scales provide an effective way to track vehicle axle weights in remote locations. This scale system allows for efficient vehicle weighing under a variety of conditions that will decrease expenses for any transport-related business through weight compliance, inventory tracking and ensuring proper vehicle loading. Included in the system is a pair of RFX® Wireless scale pads, four roll-up ramps and a wireless indicator, or PC, that fit into the trunk of a vehicle and can be deployed by one or two people in less than 15 minutes.

Minebea Intec Industrial Scale Puro

The Puro® series has been developed for varying weighing needs. Whether weighing, counting or quality control – all the Puro® scales provide a fast and accurate weighing performance. With its robust design, innovative and user-friendly applications, Puro® scales prove themselves in all areas of industrial weighing. They include a USB-C rechargeable battery with an extremely long operating time as well as smart connectivity options and application packages.

- Fast, stable and accurate results

- Increased throughput, quality and efficiency

- Large front and rear displays

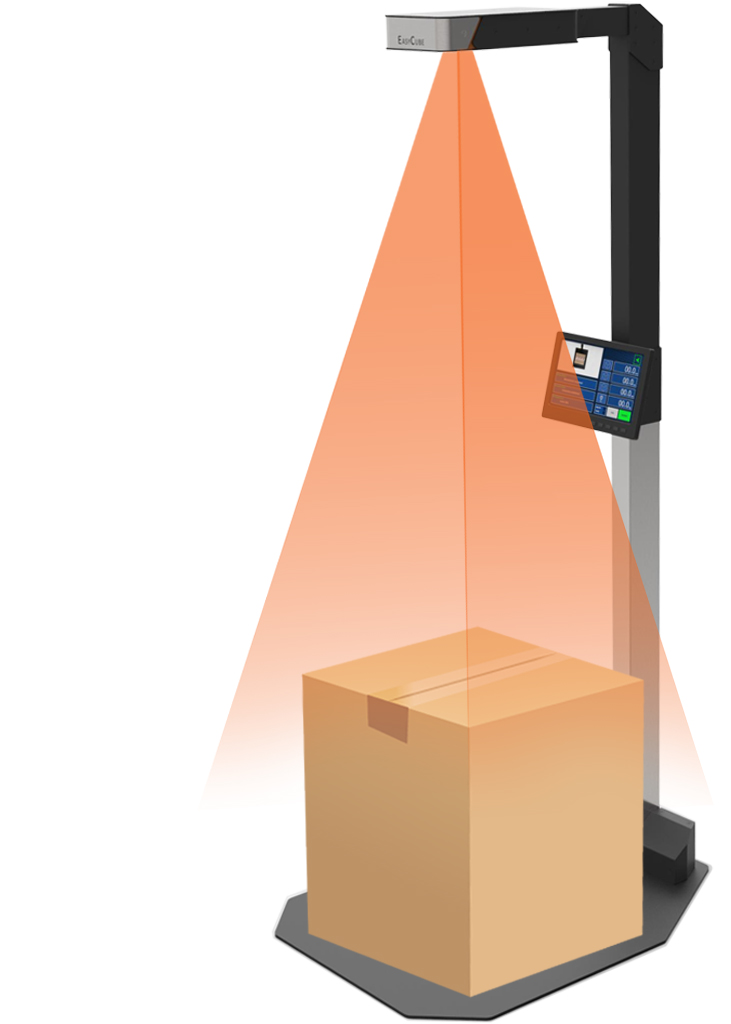

Tüm Elektronik Mühendislik EasyCube

EasyCube Volume & Weight Measuring Device

EasyCube is an instrument to find the oriented minimum bounding box of a package. It provides results as three dimensions of the minimum bounding box; length, width and height of the minimal bounding box encloses a package of any shape.

It consists of RGB-D Camera and a Single Board Computer. The Single Board Computer has a software that analyses RGB-D images and calculates the dimensions of the object. The system structure consists of horizontal pole mounted on a vertical column which holding the depth camera pointing downwards.

The RGB-D Camera used has been designed specifically for such operations. It is a stereo-vision system with two IR cameras, IR projector, RGB camera and an embedded vision processor.

The image depth and image color are transmitted via USB connection to the Single Board Computer that hosts the metrology relevant software. The software analyses images and computes object dimension measurements precisely.

Radwag HY10.16.HRP.H High Resolution Scale

Advanced HY10.HRP.H multifunctional scale enables fast and precise mass measurements in challenging industrial conditions. The scale enables carrying out measurements with very high resolutions available so far only for laboratory balances.

Robust platform made of stainless steel and high ingress protection allow to operate the scale in moist environment and at direct contact with water (e.g. meat and fish industry, etc.). The protection system against overloads and mechanical shocks ensures durability and endurance in everyday use.

Cooperation with PUE HY10 Indicator

The scale can be operated via advanced PUE HY10 indicator controlled by Linux system. Hermetic housing is made of stainless steel.

Versatility of Use

HY10.HRP.H scale is perfect for applications requiring high accuracy, precision and repeatability of measurement in challenging industrial conditions.

Uncomplicated Operation and Clear Presentation of Indications

10.1” large colour touch screen ensures excellent readability and comfortable operation. Clear menu and intuitive information arrangement on the display guarantee user-friendly performance.

Uncomplicated Databases Archiving

An extensive database enables archiving work results and periodic reports, data exchange between indicators and information import and export. Images database allows to assign a graphic to each weighing product.

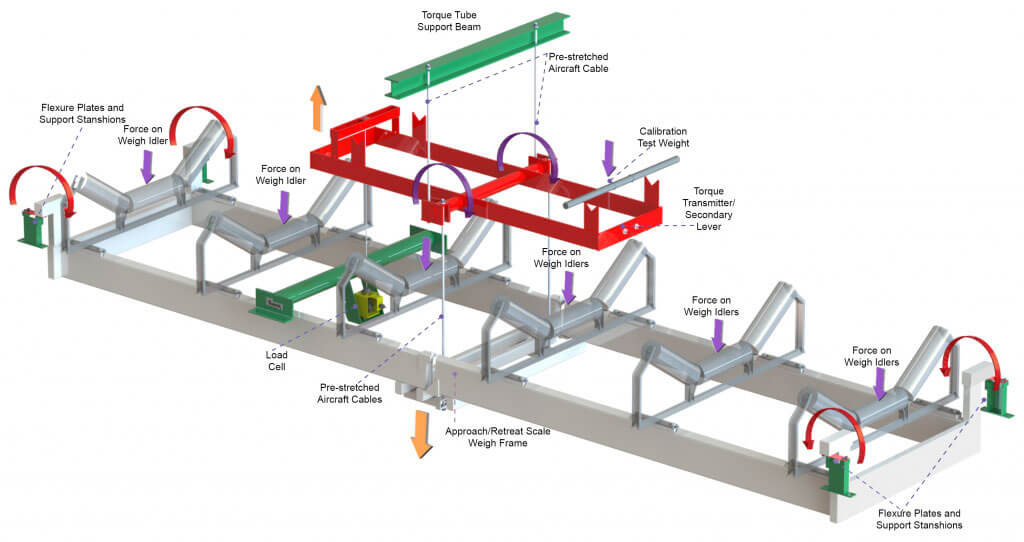

Thayer Scale 6NAR-8 NTEP Certified Conveyor Belt Scale

The Thayer Scale NAR Belt Scales are designed to deliver exceptional stability and accuracy for use in applications requiring verifiable accuracy. They are recommended for applications requiring commercial certification for billing purposes. These Belt Scales have been proven in service demanding ±0.125% accuracy through independent certification. The weigh bridge features exclusive rocking flexure suspension in the approach-retreat configuration. Measurement sensitivity is high, deflection is low, and the load cell is isolated from the error-inducing effects of extraneous lateral forces, off-center loading, foundation distortion, inclination hold-back forces, and high sporadic shocks and overloads. Tare load is mass counterbalanced to create superior signal to noise ratio in weight sensing, orders of magnitude better than belt scale designs supporting full tare load on the load sensor.

THAYER is the only belt scale manufacturer that analyzes the customer’s conveyor and application data to predict “real-world” performance. The computer program essentially tailors each component of the scale and conveyor to maximize the performance of the complete system based on the specific requirements of the application.

We consider the parameter variations that are normally experienced in conveyor installations, the lack of dimensional precision of the conveyor components and installation imperfections occurring as the result of both the initial set up and the subsequent conveyor maintenance activities, the most logical approach to designing and installing high accuracy belt weighing equipment is to design for minimum error influences in every phase of the project. This involves conveyor analysis work to seek out preferred locations for load and speed measurements within a conveyor, suspension system configurations that are least affected by conveyor influences, particularly alignment factors (load deflection vs installed alignment conditions), and many other factors.

The typical computer analysis involves inputting eleven (11) key parameters which describe the application in sufficient detail to estimate accuracy for the installation as initially defined.