Weighing Review Awards 2023

Nominated for Best Load Cells

HBK PW27A Load Cell

PW27A For Hygienic Weighing

With load cells of the PW27A product series, companies producing and filling food products are well prepared to face all future challenges: Designed for low capacities ranging from 0 to 10kg and 0 to 20kg, the load cells comply with the strict EHEDG specifications and are therefore ideally suited for filling, packing, and weighing beverages and other food products.

Due to the special design of the stainless-steel measuring body in conjunction with the solid stainless-steel pipe housing, the PW27A load cells are hermetically sealed and extremely robust (IP68/IP69K degree of protection). This allows quick and thorough cleaning, even with high-pressure washers. Owing to their integrated and encapsulated overload protection—up to ten times their maximum capacity—the PW27A load cells’ functionality remains unchanged even if someone accidentally steps on them (e.g. when cleaning the machine).

A PW27AP version of the load cell providing a connector for even faster integration is also available.

- Accuracy class: C3 multi-range

- Maximum capacities: 0–10 kg and 0–20 kg

- Degree of protection: IP68/IP69K

Scaime DVS & DVX digital load cells with industrial Ethernet connectivity

SCAIME developped DVX and DVS digital load cells for automated and dynamic weighing applications, such as rotary fillers and checkweighers.

These load cells integrate innovative electronics with a multi-protocol communication interface for connectivity to standard industrial Ethernet networks (PROFINET, EtherNet/IP...). To facilitate their integration into the network and shorten their implementation, the sensors offer a dual Ethernet port with internal switch and a web server for configuration.

DVX and DVS load cells are made of stainless steel with an IP68 / IP69K protection level well suited for wet environments and high-pressure washing. Designed to be integrated into rotary filling machines, they offer high resistance to accidental overloads and lateral forces to withstand rough handling of the bottles.

The EHEDG-certified hygienic design makes the DVS ideal for applications with stringent sanitary standards, such as food and beverage and pharmaceutical industries.

To meet the need for high accuracy at high measurement rates, DVX and DVS load cells incorporate a 24-bit analog-to-digital converter and powerful digital filters to attenuate vibration and mechanical disturbances. The sensors are also equipped with logical inputs/outputs for autonomous process control.

DVX and DVS load cells are available with two software versions dedicated to filling or dynamic checkweighing applications.

- In the filling version, the load cell directly controls the valves and takes over the entire filling process. The filling algorithm is optimized for high-speed rotary fillers.

- In the dynamic checkweighing version, the load cell automatically detects the item to be weighed and calculates its weight, on the fly, with a very high accuracy.

These specialized software programs make it possible to increase weighing rates while reducing control tolerances and thus contribute to the manufacture of more homogeneous products.

Robust, accurate and fast, the DVX and DVS digital load cells ensure the performance and efficiency of packaging machines. With their latest generation electronics integrating Industry 4.0 technologies, they offer a sustainable weighing solution consistent with the digital transformation of industrial companies.

METTLER TOLEDO SLP33xD-IOL Smart Single-Point load cells with integrated PLC connectivity and condition monitoring

METTLER TOLEDO developed a new single-point load cell family for automated weighing applications. The integrated IO-Link interface makes the new smart weighing sensors compatible with any automation control system. The integrated connectivity saves space, reduces system complexity, and allows quick and straightforward

installation. The load cell provides 200 updates per second (200 Hz), which supports highspeed weighing applications. Machine designs can be optimized for high throughput and increased

productivity. Condition monitoring and prioritized alarms (Smart5™) ensure the system is performing as expected and allow quick reaction in case of issues. Load cells are available in OIML R60 C6 and C3 accuracy classes. The best-in-class noise level of the on-board electronics and advanced noise filtering algorithms also make resolutions up to 300’000d possible. The TwinCal™ calibration technology supports loading and unloading applications. This together with onboard filtering and adjustment for temperature changes enable precise weighing results in any application. The new load cell family is available with rated capacities from 10 kg up to 500 kg, and with IP67 ingress protection rating.

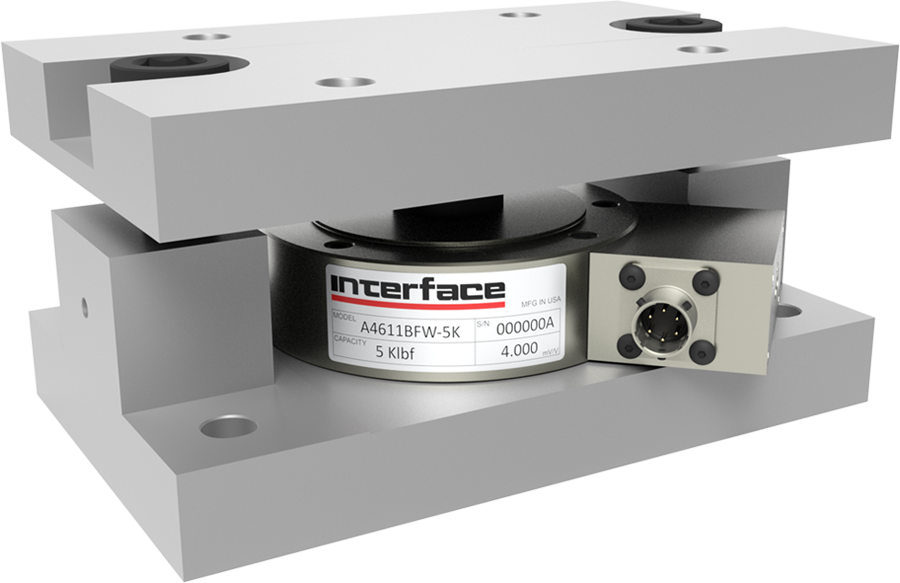

Interface A4200 WeighCheck Load Cell

Interface A4600 WeighCheck™ Load Cells in stainless steel and A4200 WeighCheck Load Cells, which is zinc plated, are both high accuracy force measurement weighing solutions. Manufactured and designed by Interface engineers, these exclusive Interface products are specifically designed for tank weighing, where it is necessary to accommodate expansion and contraction of the tank. Interface has expanded with new model options that include signal conditioning features, including IO-Link Digital and 3-Wire.

Standard A4600 and A4200 WeighCheck Load Cell features include:

- Capacity ranges from 2.5K to 50K lbf (11.1 to 222 kN)

- High output – 4 mV/V

- Self-centering in all directions

- High safe side load – to 400%

- Standardized output – ±0.1%

- Zinc plated (A4200) or stainless steel (A4600)

- Factory assembled for easy field installation

- Static, dynamic and in-motion capabilities

- Low height – 4.0 in (101.6 mm) for 2.5K, 5K, 10K (11.1, 22.2, 44.5 kN); 5.0 in (127 mm) for 25K, 50K lbf (111, 222 kN)

Interface offers fully engineered to order and custom options to our WeighCheck load cell models that include our new A4200 and A4600 IO-Link Digital Load Cells with an industry stand M12 connector. IO-Link, a communication protocol used in industrial automation applications to connect sensors and actuators to control systems has multiple benefits. These include increased flexibility, enhanced diagnostics, simplified wiring, improved efficiency, and lower costs.

The newly introduced customized A4200 and A4600 3-Wire Amplified Load Cells provide an internally amplified low profile load cell with a voltage or mA signal.This option eliminates the need for an external signal conditioner and comes scaled to the load cell and ready to use.

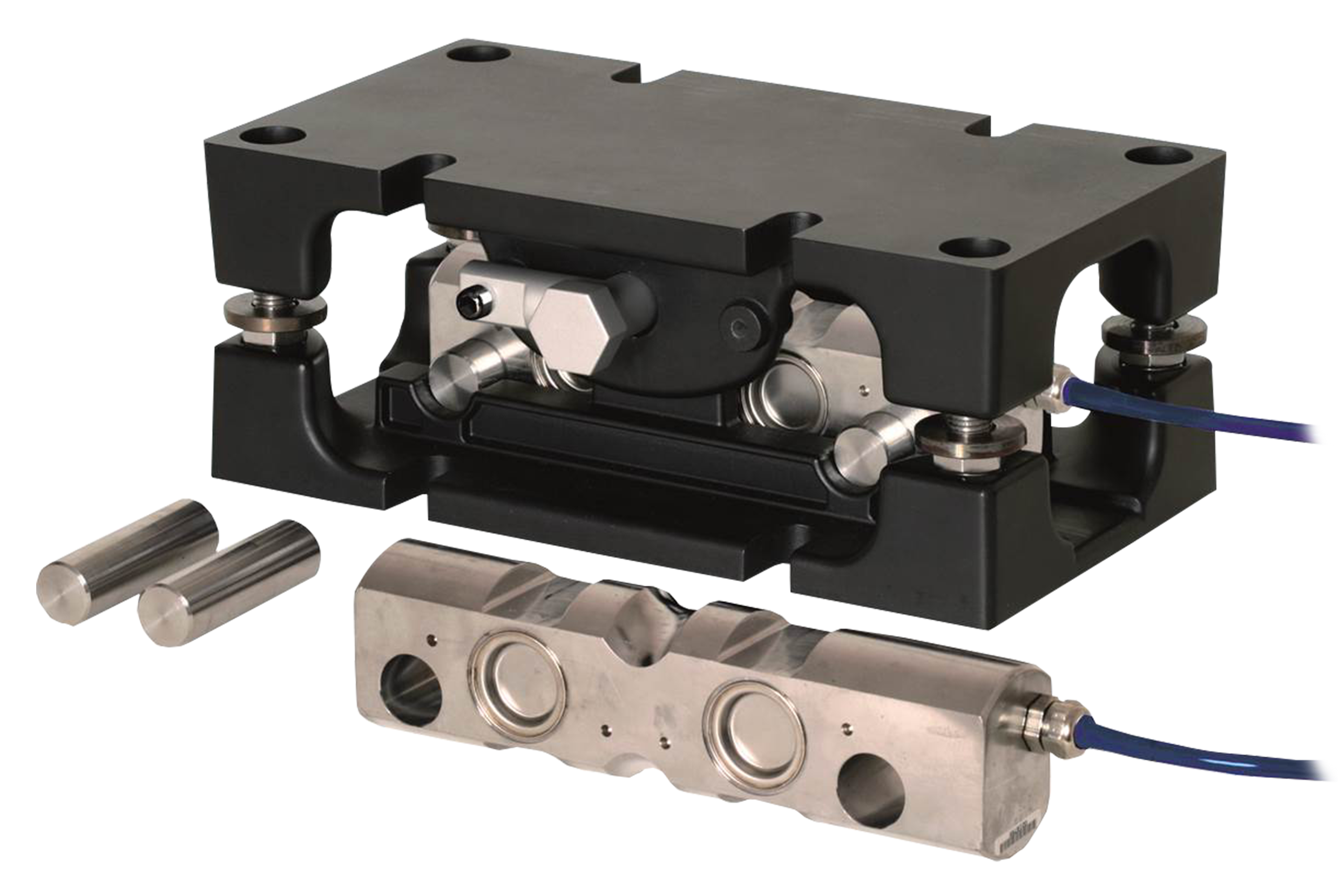

Thames Side VC3500 Double Ended Shear Beam Load Cell with Patented MasterMount®

Thames Side’s model VC3500 double-ended shear beam load cell with the patented MasterMount® is the best-in-class solution for silo and hopper weighing systems. The MasterMount® was primarily designed for safe and easy installation without the need for any hydraulic lifting jacks or special tools. While conducting any kind of maintenance work like welding, this particular design removes the need to replace the live cells with dummy cells. Self-captivated pins are used, instead of regular retaining clips to retain the stainless steel VC3500 load cells. The MasterMount® accessory itself provides the lift-off protection, as an alternative to the traditional method of using the load cell for lift-off protection. If required, installation and removal of the load cell can be done in only a few minutes, which saves a huge amount of installation cost.

The VC3500 double ended shear beam load cell with MasterMount® accessory has the following features:

- Patented alloy steel mounting accessory and hermetically sealed stainless steel load cell

- Protection according to IP68 and IP69K class

- Suitable for silo weighing installations with individual load cell capacity ranging from 2 tonnes to 30 tonnes

- Installation and removal/replacement of load cell can be done QUICKLY WITHOUT any hydraulic jacks or special tools

- Load cell can easily be installed or removed in a loaded silo

- No jacking screws or supports; considerable anti-lift off protection via MasterMount® accessory

- Very safe, accurate and cost-efficient solution for process weighing applications

- Load cell is available in ATEX approved version for explosive / hazardous areas

- High temperature version is available

- Parylene coated load cell is available for use with aggressive environments

Eilersen Capacitive Compression Load Cells With Integrated Lift-Off Protection (DLC and DMC series)

Eilersen has launched a new set of capacitive load cells with integrated lift-off protection in a EHEDG compliant hygienic (aseptic) design – without any gaps or edges for easy cleaning to minimize the risk of bacteria growth. This unique design has been patented worldwide.

The load cells are available with a capacity up to 50000 kg with up to 0.025% accuracy, and are able to tolerate overloads up to 1000%, due to the robust capacitive technology.

These robust digital compression load cells are very suitable for a range of high demanding applications including tank weighing, process weighing, high shear mixers, big-bag equipment, outdoor silos, offshore, and installations in seismic areas.

The load cells are produced in electropolished stainless steel and hermetically sealed to IP68 and are available with ATEX (Ex) and IECEx applications (Zone 1, 2, 21 and 22). All load cells are developed and produced by Eilersen in Denmark.

UTILCELL MODEL 350 Shear Beam Load Cell

UTILCELL (Spain) – The load cell Model 350 (300…10.000 kg), together its mounting kits, have been designed for robust and accurate weighing in industrial processes of tanks and hoppers, with multiple advantages:

- Model 350i version: Fully stainless-steel construction. Hermetically sealed with the highest protection degree IP 68 and IP 69K.

- Model 350a/n version: Stainless steel or nickel-plated alloy steel construction. Silicone sealed with IP 66 protection degree.

- Globally used in legal weighing systems. OIML R60 Class C 3.000 divisions and NTEP Class III & IIIL 5.000 and 10.000 multiple cell.

- Highly recommended load cell for any type of tanks and hoppers in industrial weighing applications.

- High repeatability and high accuracy of the weighing values.

- Accessories available in several versions:

- Improved force transmission to the load cell due to a ball-based joint, giving the best accommodation in cases of thermal expansion, structural torsion, and deflection.

- Rubber silent-block for higher impact and vibration protection.

- Load foot for industrial 4-load cell platform scales.

- Superior safety systems for the utmost reliability:

- Easy installation in the tank and hopper supports, with or without the load cell.

- Blockage bolts for transport protection of the load cells.

- Upper plate with conical holes for self-centering.

- Integrated lift-off prevention system.